The Reason

The slimmest flying tourbillon movement produced (2022).

Functions

Manually wound Flying Tourbillon movement with minute and hour hands time indication.

Technical Specifications

Movement reference BVL268. Manual-winding. Movement diameter 36.2 mm, thickness 1.95 mm. Number of parts 253. Number of jewels 11. Power-reserve 52 hours. Frequency 21.600 v.p.h. (3Hz). Case material titan, diameter approximately 40mm. Front and back glasses made from sapphire. Water-resistance 3 bar (30 meters).

The slab-like case is rigid and strong in design and combined with being made from titanium ensures that despite its thickness (or thinness) it remains resistant to conventional wear.

The integrated bracelet removed.

Views from the rear of the watch showing the movement through the back sapphire.

The bracelet is fixed onto the case with a long spring bar, additional strength is added to the construction by the two pins protruding from the normally hidden flat surface at the end of the bracelet, shown below, that in turn enters the case head elongated holes.

The case is held together by 8 pentagon headed screws/bolts. Below can be seen the tool used to tighten and loosen the screws. The screws traverse the case back and tighten into the bezel holding the construction together.

The 8 case screws removed and the bezel sitting next to the assembled watch.

The movement is fixed into the case by 4 screws accessed once the bezel is removed, and situated around the dial. Once these are removed and the winding crown detached through the release mechanism of the split stem, the movement can be freed from the case.

The underside of the bezel shows the seal insuring the case is water resistant and the 8 integrated pillars that position the bezel and in which the case screws tighten it in place.

The winding crown is screwed onto a split stem. The full stem can not be removed from the movement from the dial side and no access is granted from the rear of the watch. This system allows the winding crown to be disengaged from movement permitting the movement to be removed from the case.

The hands and movement-case, screws removed.

The movement with winding crown removed and sitting outside of the case. The winding crown including the end section of the stem is then returned to the movement.

Between the movement and the case are four hard rubber washers (one shown below). These allow a security in the event the case receives a severe knock or external pressure that could result in slight temporary deformation in the flatness of the assembled case, preventing the movement from being compromised and temporarily stopping or slowing down.

The rubber washers also act as a security in case there are any small variations in the flat machining either on the main plate or the case itself.

Below: The bottom left screw head is an eccentric plug that locks the dial foot into position. Above it is the pinion that winds the barrel ratchet wheel and the final screw to the right is one of the 3 ball-race assemblies that the barrel turns upon.

The dial is positioned onto the movement with two dial feet.

Although not visible, hidden under the dial, all of the components are decorated.

The movement removed from the case and the winding crown replaced. The winding crown is replaced be able to let down any remnants of power from the mainspring and to aid in assembly, as well as manipulation of the calibre.

The setting mechanism is simple and solid and the setting/winding concept avoiding conventional 90 degree gearing to reduce thickness. Both the winding and setting is driven by the teeth on what is conventional the sliding pinion.

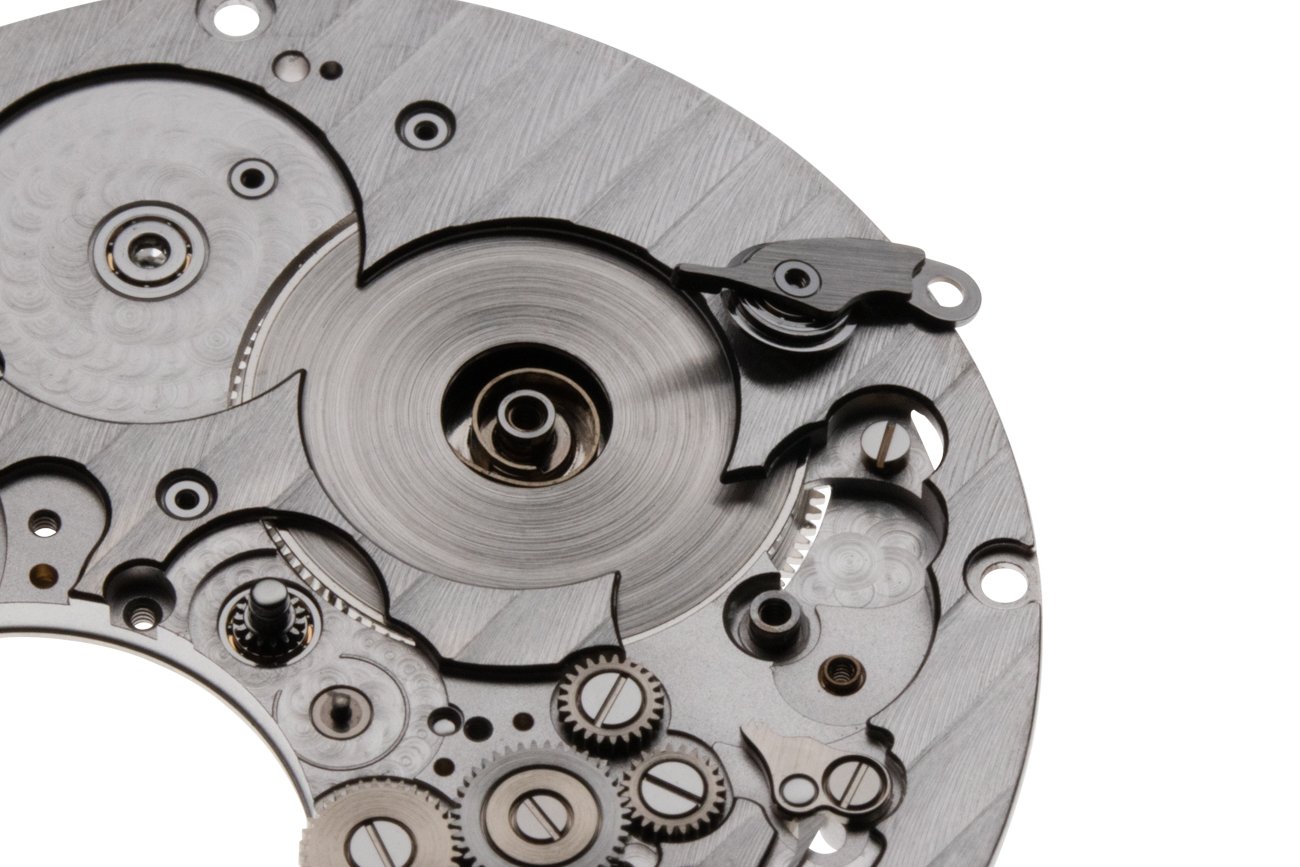

The rear of the Flying Tourbillon cage assembly.

The large solid wheel is made from rhodium plated brass and is the underside of the barrel (containing the mainspring) and drives the pinion above it (linked to the motion-work that turns the hands) and to the left the pinion that transmits power to the going train leading to the Tourbillon cage.

The Tourbillion is driven by the wheel to its left meshing with the teeth that are cut into the external diameter of the cage itself.

The final wheel driving the cage removed and the bridge that holds it in position. This wheel is driven by gears that are located on the underside of the main-plate.

The minute wheel and its cock removed. These pieces as well as those shown in the above image are removed first in order to allow the Tourbillon to be removed.

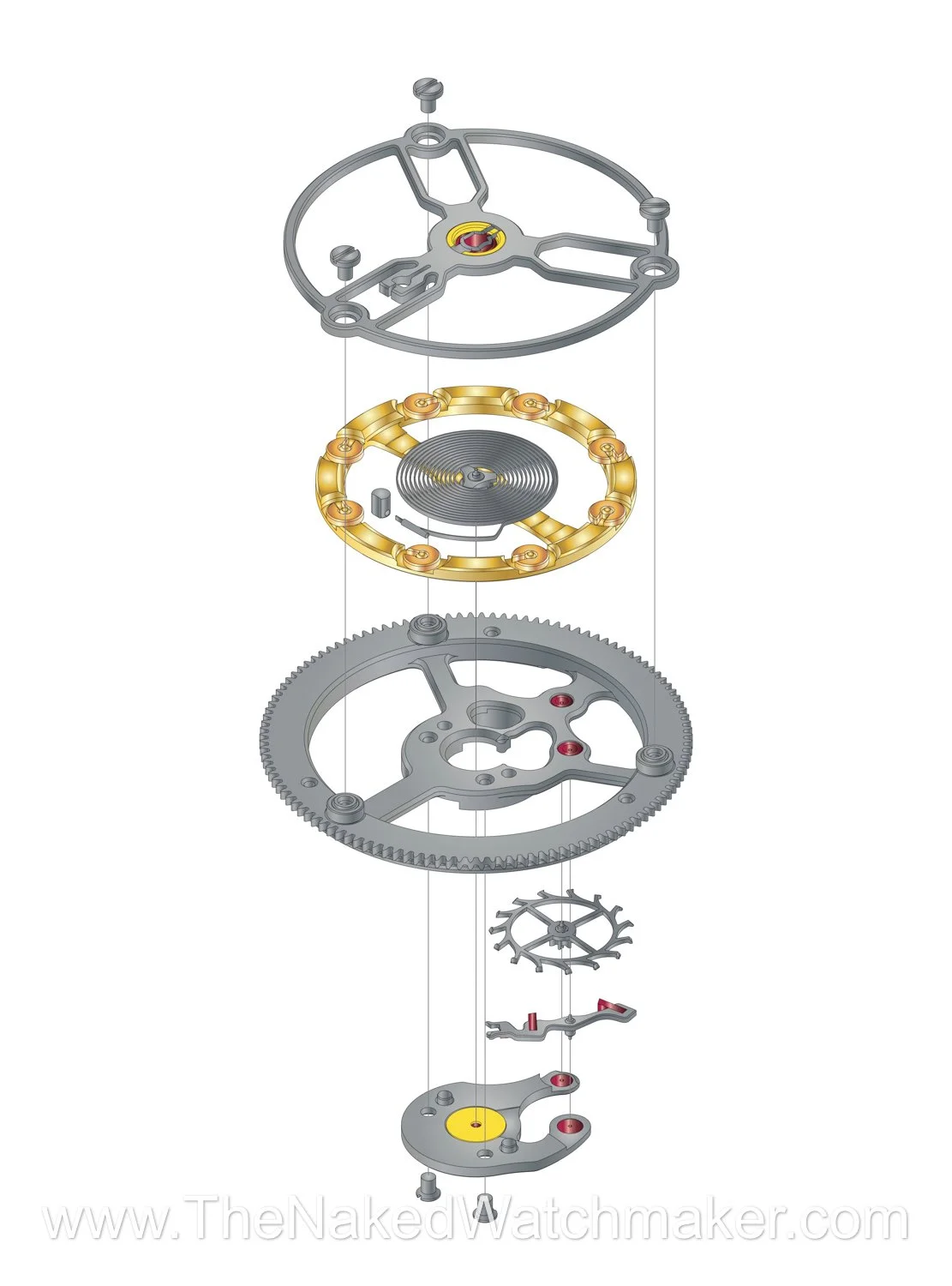

An exploded view of the dial-side of the movement.

The cage assembly is held in place by 3 screws set into the main-plate. Below the screws are removed and the cage moved.

The Tourbillon cage turns inside of the exterior large ring that is a ball race, avoiding central pivoting and resulting in a flying Tourbillon turning on the exterior diameter of the cage.

Recto-verso of the Tourbillon cage.

The balance and upper cage bridge removed.

The escape wheel and lever removed. The bridge that holds them both in place also houses the Incabloc in which the balance pivots.

An exploded view of the Tourbillon cage

The partially dismantled Tourbillon cage. The balance wheel is free-spring (no index to adjust the regulation). The regulation is made through adjusting the small collets found flat on the balance upper outer surface.

The ratchet wheel and barrel arbour are riveted together and shown below upside down next to the barrel. In the centre of the barrel can be seen the inner coil of the mainspring.

The third and adjustable ball-race upon which the barrel turns removed. All three need to be removed in order to remove the barrel.

The three ball race assemblies allow the barrel to turn through contact on discs set around the ball races that guide the barrel though a cutout slot in the outer barrel wall.

One of the ball race assemblies can have its depth of penetration into the barrel adjusted through turning an eccentric plug ensuring there is neither too much play or too little and causing the barrel to bind.

The long spring below pushes on the click that prevents the ratchet wheel from unwinding by allowing the pinion it engages with to turn in only one direction.

The main-plate dismantled except for the setting mechanism, canon pinion upon which the minute hand sits in the centre of the movement and the winding/setting pinions.

Summary

The Bulgari Finissimo Flying Tourbillon despite its 1.95mm thickness remains solidly constructed and easy to dismantle and re-assemble. The decoration is a mix of industrially executed Geneva stripes, hand grained levers and springs.

The overall concept is executed with a common-sense approach to the goal of developing an ultra-slim complication. To achieve this the calibre exploits both sides of the main-plate in assembly instead of the conventional assembly from primarily one side. And a barrel that instead of pivoting on a central barrel arbour, turns on three exterior ball races that support the outer vertical wall of the barrel.

The complete modular cage and ball race are dropped into place as a single assembly. The setting/winding mechanism is simple, solid and by avoiding the conventional 90-degree gearing helps reduce the overall thickness of the mechanism.

The final result is a holistically well thought out solid timepiece with subtle but innovative elements.

GALLERY

In the grid below are both images used in the description of this page plus more. Please click on the image to enlarge and see in full.

To learn more www.bulgari.com