The Reason

An interesting and little known manufacturer of calibres both simple and complicated, making their own balance wheels and balance springs. Below is a deconstruction of one calibre, the modular nature of the design allows for diversification between automatics and manual wound as well a multiple different functions and modules.

Schwarz Etienne has existed since 1902. In 1902, Paul Arthur Schwarz and his wife Olga Etienne founded the Schwarz Etienne company in La Chaux-de-Fonds.

It worked within the various brands it owned, such as Venus, Alpha, Sultana Le Phare and Astin. Schwarz Etienne’s has also had many partnerships supplying movements to large brands, such as Chanel, Dunhill, Mauboussin and Caran d’Ache.

The company, which was taken over by the family’s sons in 1940, Schwarz Etienne progressively extended its business across Europe and also across Asia and the Near-East. In the middle of the 1960s, the watch manufacturer enjoyed growing success. It attracted prestigious clients, such as the Vatican and Leonid Brezhnev (the then Chairman of the Presidium of the Supreme Soviet).

Following a broad diversification of its production in the 1970s and 1980s and in order to alleviate the watchmaking crisis, from 1985 onwards the company decided to return to its original know-how, i.e. the creation of movements and watches. During this period, it developed its own brand and its own collections, and progressively became a watch manufacturer in its own right.

In 2003, Chaux-de-Fonds business man, Raffaello Radicchi, bought the Schwarz Etienne company.

ASE 220-00 AUTOMATIC CALIBRE

(With small seconds at 6 o'clock, and central GMT indicator)

ASE220, 34 jewels, 86 hours power reserve, frequency 3hz (21600vph), number of components 213.

MSE 211-00 MANUAL WOUND CALIBRE

(with power reserve indicator)

MSE211, 37 jewels, 96 hours power reserve, frequency 3hz (21600vph), number of components 230.

Deconstruction of the automatic calibre ASE -220-00

Click on the first image below then the arrow to the right of the image to follow the deconstruction image by image, touch the image to see the accompanying text.

Profile showing the unique serial number of each calibre engraved on the side of the mvt.

Dial side of the mvt

Close-ups of assemblies.

Lubrication/assembly chart for the automatic mechanism

The barrel with the barrel cap removed showing the main spring. Historically one of the most important technological developments in watchmaking was the unbreakable mainspring, made using alloys which do not fatigue over time as with their ancestors, which made in carbon steel. Pl made us an 'S' form which would improve the consistency of the transition of power through the train whether fully wound or or wound down.

Individual components

Lubrication/assembly chart for part of the retrograde mechanism

The majority of the bridges above are not angled but everything can be, a S-Etienne bridge below illustrates this. The decoration of the bridges is specifically at the request of the final clients. On all movements which are sold under the S-Etienne brand, the bridges are angled. View their site http://www.schwarz-etienne.ch/ to see examples.

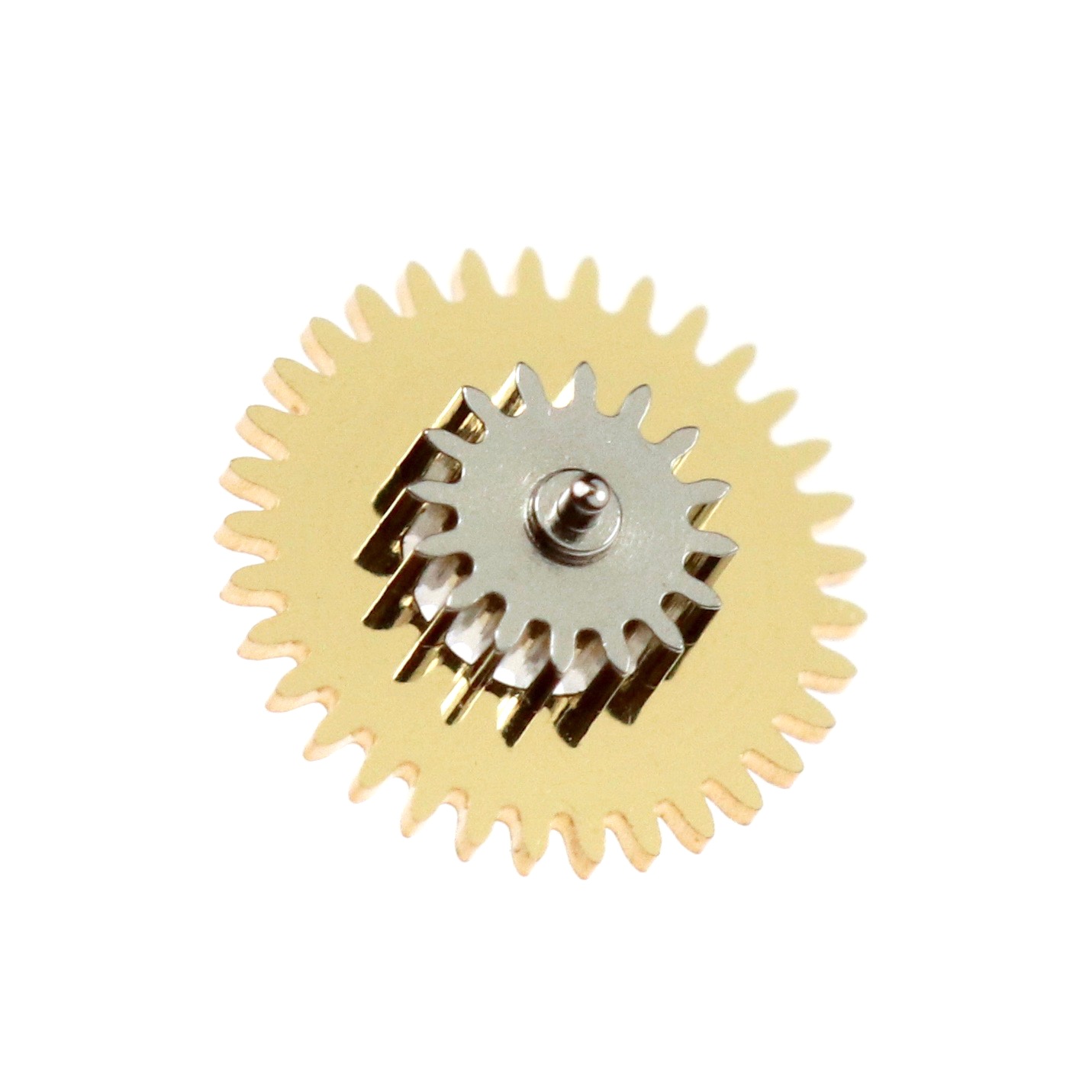

All wheels are made in brass, circular grained on both sides then plated before having the teeth cut to assure metal on metal contact between brass and steel. All pivots are are burnished after they have been decorated.

Above in the centre is a close up of a reverser wheel for the automatic, the small satellite pinions allow for mvt only in one direction blocking in the a-posing.

Below are additional examples of S-E calibres

To learn more about Schwarz Etienne www.schwarz-etienne.ch