The Reason

Spring Drive is a unique movement that brings together mechanical and electronic watchmaking.

Introduction/function The SBGA211 is powered by Spring Drive, Seiko’s unique caliber, combining the motive force of a mainspring found with the precision of a quartz watch. The small hand at 7.00 on the dial is the indication for the power reserve. The case and bracelet are made with high-intensity titanium. Scratch and corrosion resistant finish, (40% lighter than stainless steel).

Technical Specifications

The movement caliber is 9R65. Movement Type: Spring Drive, automatically wound. Power reserve: 72 hours. Accuracy: ±1 second per day / ±15 seconds per month. Case Material: High-intensity titanium, (40% lighter than stainless steel). Glass Material: sapphire. Glass Coating: Anti-reflective coating on inner surface. Case size: Diameter 41mm × Thickness 12.5mm. Water resistance: 10 bar/100 meters.

Please move the cursor across the image below, (or by finger on a smart phone), to rotate the watch.

The case back with sapphire crystal is screwed in place using a 6 fingered key.

The movement is held in place by 2 large movement clamps that cross the movement ring and hook into the case centre. When removed (with the stem) the movement exits from the case back side.

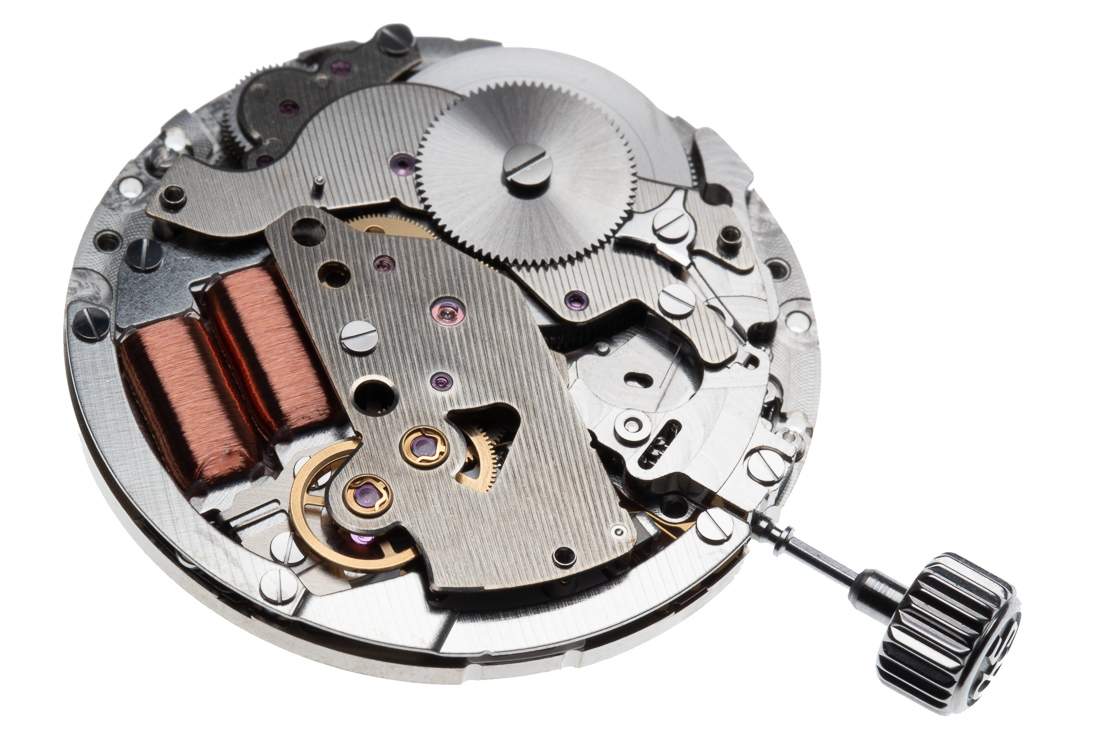

Recto-verso of the movement removed from the case, with the movement ring in place.

The name of the model ‘Snowflake’ associates to the finish of the dial. The inspiration for the dial and name is derived from the snow on the mountains that surround the Shinshu Watch Studio in Nagano Prefecture where the Spring Drive is made.

The movement with and with out the hands.

The 3 dimensional highly polished aspect of the batons and hands are part of DNA of Grand Seiko.

The tubes being riveted onto the hands.

The hands being adjusted to the correct form.

The final hands ready to be used.

Recto-verso of the Snowflake dial.

Recto-verso of the movement with the dial and movement ring removed.

Below: One of the coils located to the left of the the gold coloured wheels.

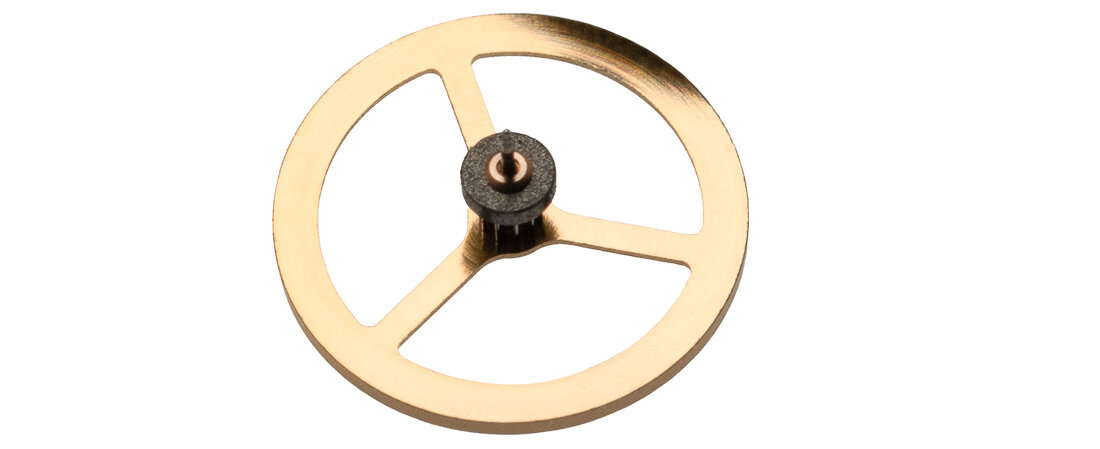

The rotor removed.

The Rotor

The decoration on the surface of the rotor and bridges although resembling traditional Geneva Stripes is executed differently. Conventionally, each stripe is developed through the material being removed from the surface of the component by a sanding process using abrasive papers/ impregnated rubber blocks or similar. Here a sharp diamond cutter set at an angle turns in a circular motion cutting away at the surface. The final aesthetic is very much "Grand Seiko" opposed to any other brand and becomes part of the decoration DNA of the brand.

The movement with the upper bridge removed.

Recto-verso of the upper bridge that supports the rotor and part of the winding mechanism.

The automatic winding system (developed in 1959 by Seiko) remains effective today and winds the mainspring when the rotor oscillates in both directions with the ‘magic lever’ pushing and pulling the transmission wheel as the rotor turns.

The ratchet wheel and click.

The upper train bridge.

The upper train bridge removed showing the electronic side of the calibre.

The barrel and gear train which drives the spinning regulator glide wheel.

The inversed glide wheel with circular magnet in view.

The gear train removed showing the circuit board for the tri-synchro regulator.

Recto-verso of the circuit board.

The large double coil.

The electronic parts removed.

The gear train which associates with the power reserve indicator.

The dial side of the calibre with the cover plate for the calendar mechanism removed.

An explanation of how the Spring Drive mechanism works.

(Courtesy of Grand Seiko)

Summary

The Spring drive was developed approximately over a 20 year period. The goal was to develop an accurate timekeeper combining the accuracy of quartz with the longevity of a mechanical calibre. The fusion between two worlds of watchmaking results in a unique concept with a smooth gliding seconds hand.

To learn more about Grand Seiko