The Reason

The Simplicity series by Philippe Dufour is one of the most collectable of any modern hour, minute, seconds watches made by an independent watchmaker.

The first Simplicity shown was made 17 years ago. It is 34mm in diameter, a prototype made in white gold. There are differences between this model and the later versions which include the size of the jewels used as well as the type of balance wheel that followed in later versions. The number of this watch is -000- machine engraved, all later pieces were hand engraved by Kees Englebarts.

Representing this deconstruction are 3 watches, the original Simplicity from 17 years ago, a kit of components prior to being finished and an advanced mvt yet to be adjusted and cased up.

The first Simplicity made, 17 years ago.

Please click on the images below to enlarge and to read additional information.

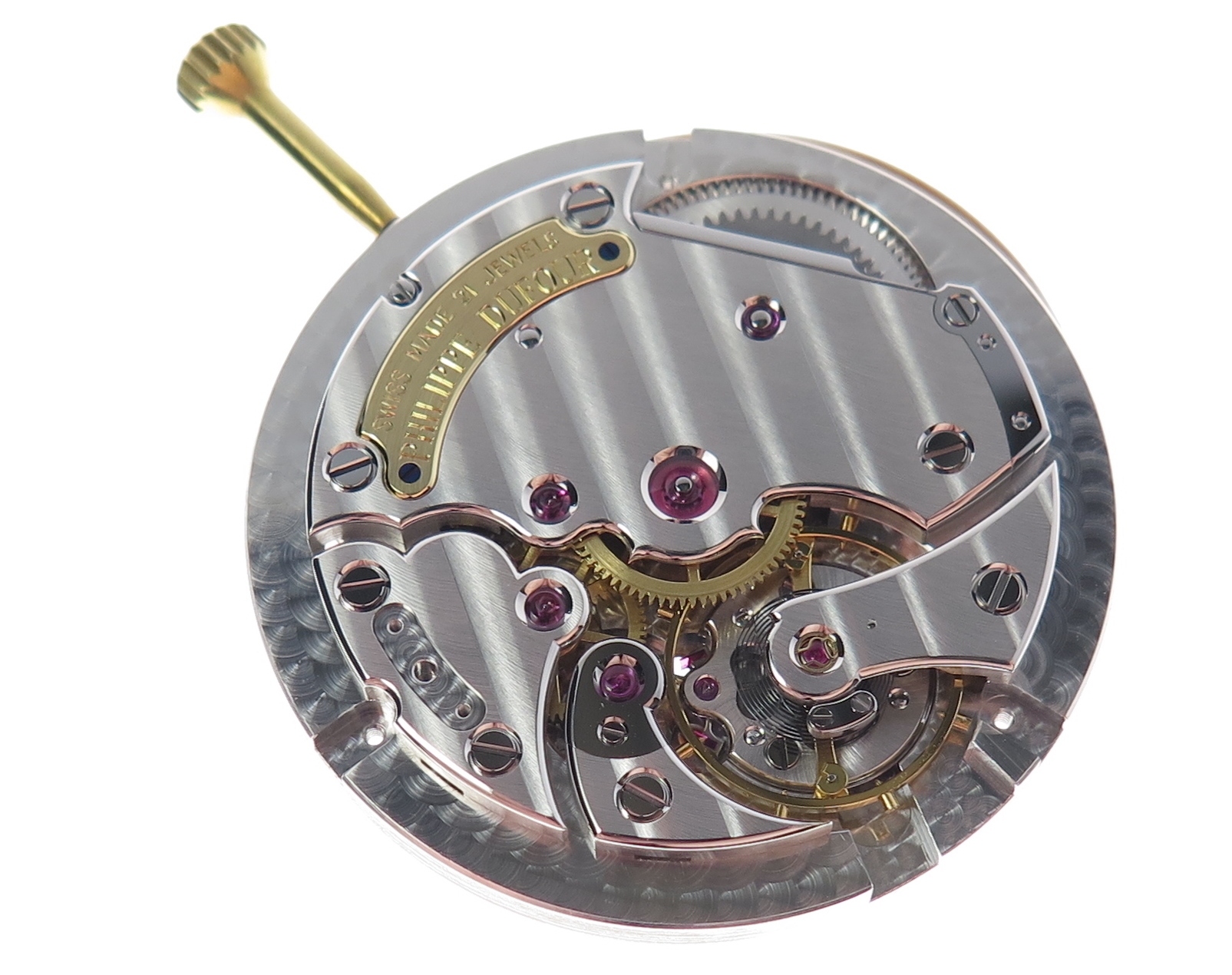

A view showing the fully assembled watch and the effect of the Geneva stripes brought to life by light. As the watch is moved light catches the Geneva stripes differently altering its aesthetic.

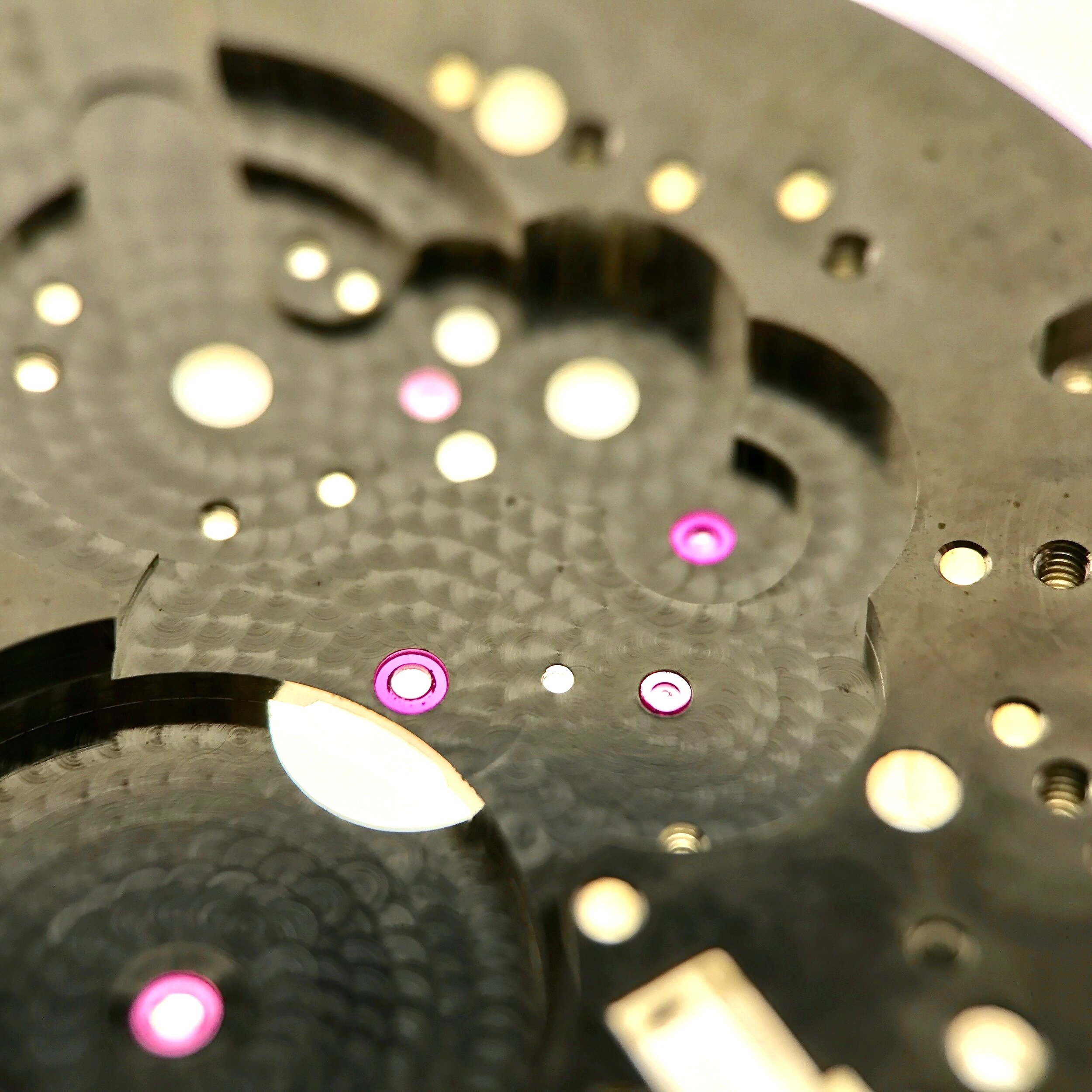

The images directly below are from a Simplicity movement in the early stages of being built. The majority of components are not yet decorated.

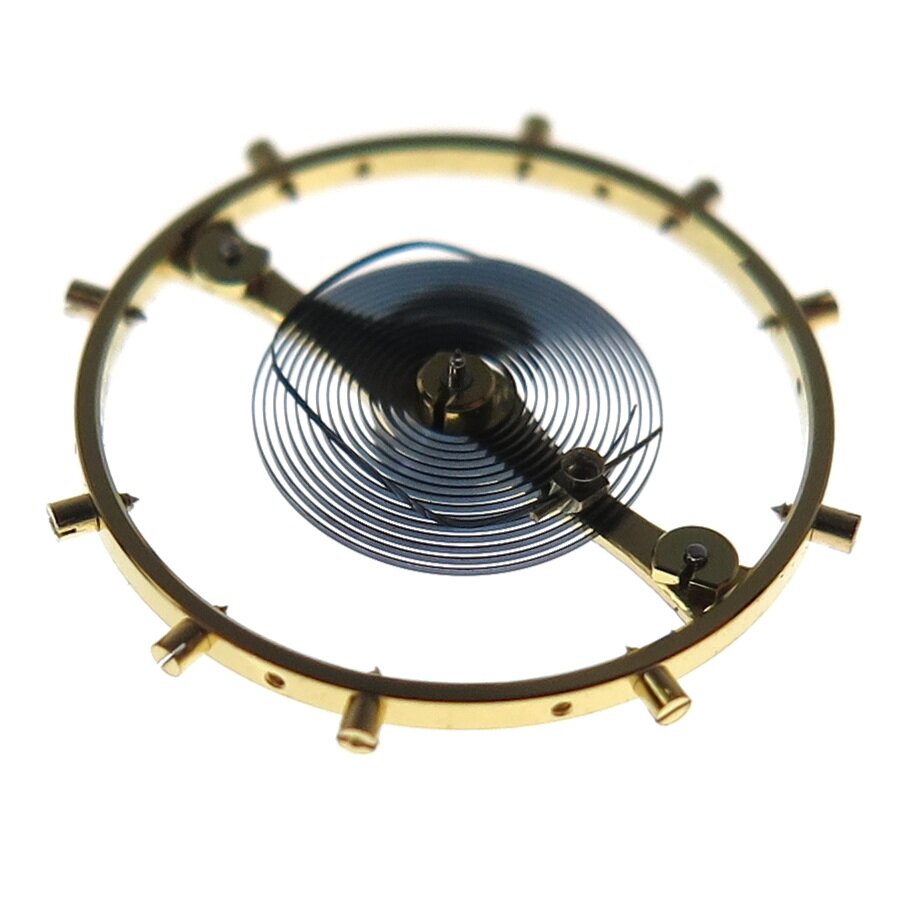

The full gear train, including barrel, ratchet wheel, upper crown wheel, balance and escapement.

Explosion of the principle parts of the movement mostly before decoration.

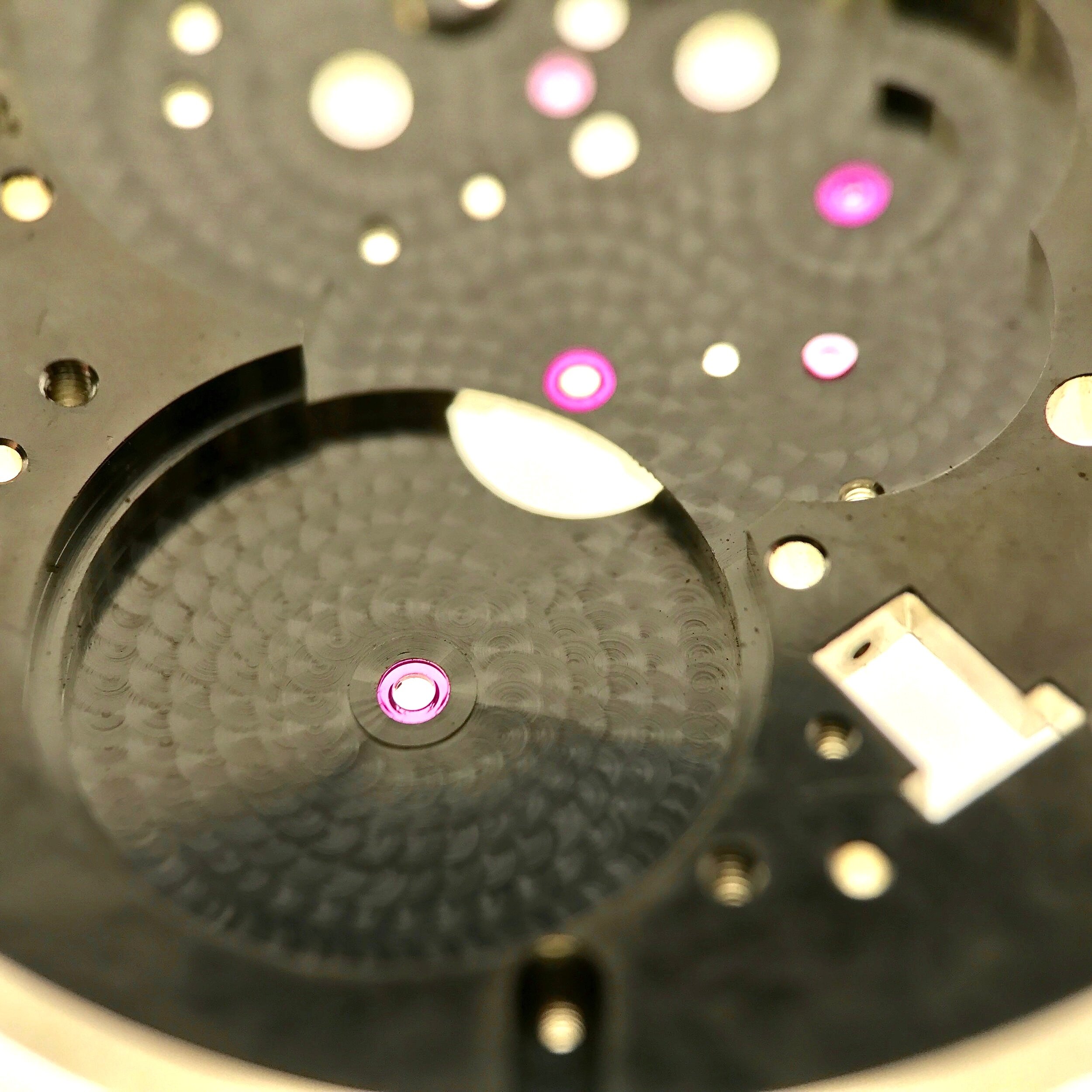

The images below are of a movement that is advanced and soon to be cased.

The plate for the series number at this point has not been added

Assembled under dial view of the movement.

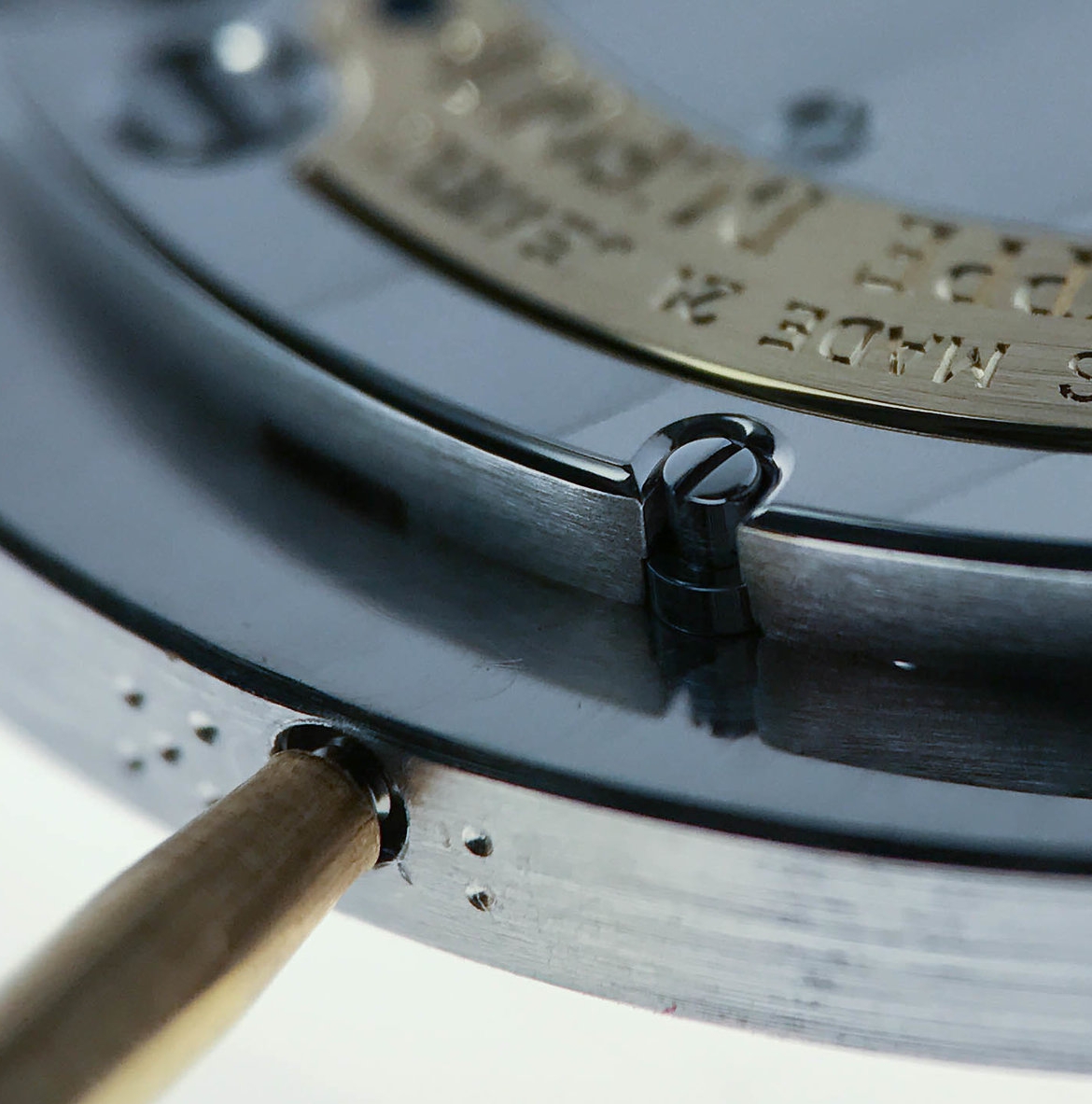

Diverse views of a Philippe Dufour Simplicity

Images from Philippe Dufour's workshop

To learn more click on www.philippedufour.com