The Reason

Originally launched in 2013 the EMC was the first mechanical watch with an integrated electronic system, manually charged, allowing the owner to both monitor the precision of the mechanical movement through a subsidiary dial and physically adjust the regulation if needed without entering the watch.

Functions

Central minutes and hours indication. Bottom left, 80 hour power reserve indicator. Top left, precision delta (for regulation purposes). Top right, seconds.

A note from URWERK - To monitor and evaluate the mechanical movement, an” electronic brain” was needed. Olivier Evalet, a software developer was instrumental in the project: "The idea was to use precision optics, i.e. light, to measure the precision of a mechanical movement. The accuracy we managed to achieve is better than 10 microseconds. And we have created a reliable system that is designed to work over the long term. The power for EMC's electronic "brain" derives not from a simple battery but a super-capacitor that even after 100,000 to 200,000 charge/discharge cycles loses very little performance. We also chose a high-frequency oscillator with extremely long life – its instability is only 3 parts per million over a full year."

The case back material is titanium, case front 316L stainless steel. The finish prior to the black PVD treatment is a combination of brushed and sand blasted surfaces.

Regulation

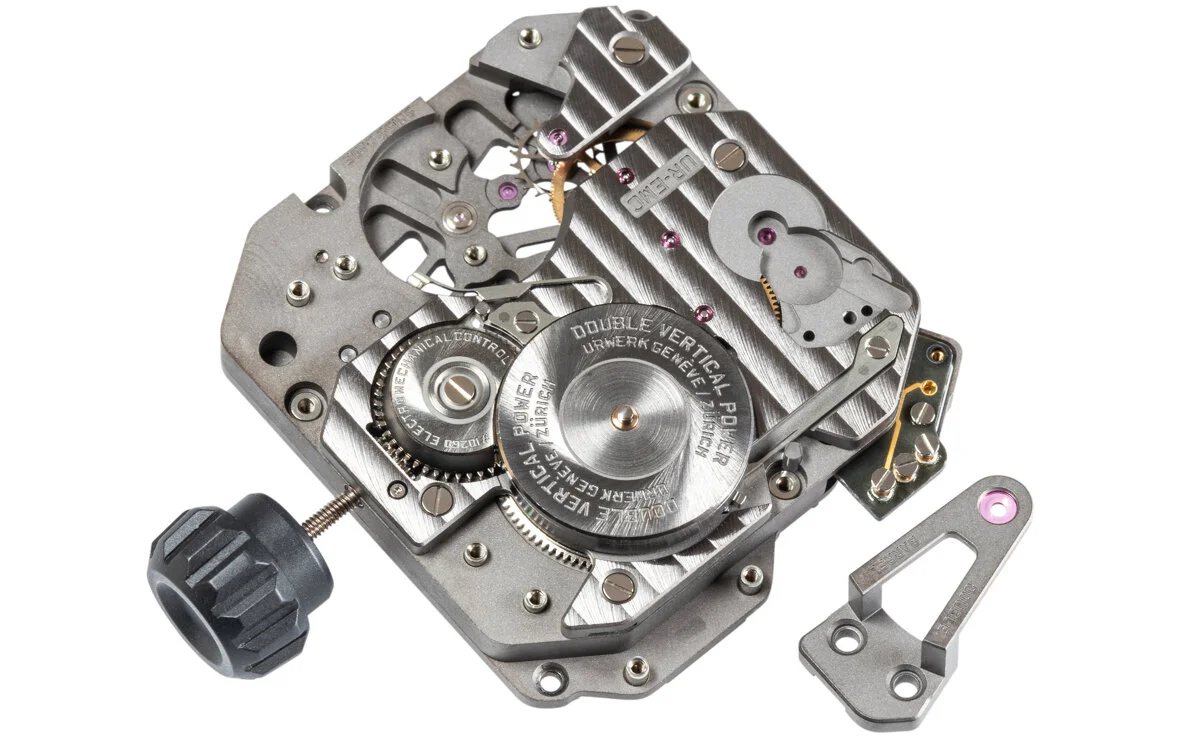

The timing adjustment screw in the centre of the image can be turned and allows the user to make fine adjustments to the balance rate regulator.

The low positioning of the strap on the back of the case held in place by 4 long stainless steel screws, allows the strap to pivot, to follow easily the contour of any wrist size.

Technical Specifications

Case material: titanium and steel. Dimensions: 43mm width, 51mm length, 15.8mm height. Crystal: Sapphire crystal. Water-resistance 30m / 3ATM.

Movement: UR-EMC calibre inhouse URWERK. Escapement: Swiss lever. Balance wheel made in ARCAP P40 coupled to the optical sensor. Balance frequency: 28,800 vph – 4Hz. Balance spring: flat. Barrels/power reserve, two vertically mounted mainspring barrels, connected in series running for 80 hours.

Generator EMC system; Maxon® generator with manual winding charging super-capacitor. Optical sensor controlled by an integrated circuit board; 16'000'000hz reference oscillator.

Profile, showing the crank that is used to charge the capacitor, powering the electronic measuring system of the watch.

The crank clips into the case when not in use.

The function of the side button

The crown at 6 o’clock is used to wind and set the time. After the capacitor has been charged by turning the crank 15 times, the button at 8 o’clock on the case is pressed and held for 3 seconds, this activates a hand that shows the rate of the watch in the red zone of the dial.

(The rate: the gain or loss resulting from the pulsing of the balance wheel.)

The crank partially extended from the case centre.

The video below shows the functioning of the measuring device.

(Reproduced courtesy of URWERK)

The balance wheel, optical sensor and circuit board are all found underneath the red grill and bridges seen from the case back.

The escapement and wheels are virtually all hidden in the design. The most prominent piece of the train visible is the upper barrel drum.

6 o’clock winding crown view, showing the plate representing the number in the limited edition of the model.

12 o’clock view, crank to the left, generator set into the section above the strap screws.

3 o’clock side, crank view.

9 o’clock view, access to the generator (G) to the left, the capacitor far right and off-centre right the button activating the measuring function.

The red arrow indicates the direction the crank should be turned to enable the generator to charge the capacitor.

The crank assembly is held in place by a combination of the two screws shown removed from the case and a 3rd large ‘nut’, unscrewed using a specific tool which enters the 4 holes in the centre of the crank assembly.

The screwdriver used to remove the screws/bolts from the case back and sides.

The case back screws removed.

The case black is PVD, the red parts anodised, the dark grey main bridge ruthenium plated and the barrel rhodium plated.

To place the winding crown into the setting position the below button is pushed down. As it pivots between the long grey strap screws it pushes the winding crown into the setting position, enabling the user to set the hands.

The large and extended steel screw to the right both holds one side of the strap as well as creates the pivoting axis for the rear setting button.

The case slightly opened revealing the rubber seal that sits in a milled out gully around the side of the caseback.

The case back removed revealing the full circuit board for the measuring device.

The inside of the caseback with the red grill fixed in place.

The red cover removed revealing the optic sensor and the balance wheel, plus index and stud for the balance spring.

The accuracy of the optic (visual) sensor carries an advantage over that of a traditional 'Witchi' timing machine that measures the audio sound of a beating balance wheel, because it links directly to the site of the balance wheel giving a clearer reading rather than through bridges, cases and microphones as is conventionally the process.

The EMC timing rate monitoring unit was developed to include:

1. An optical sensor on the balance wheel capturing the precise rate of oscillation of the 4 hertz / 28,800 vph regulator, over a period of 3 seconds. This sensor consists of a transmitter and a receiver positioned either side of the balance, and is triggered manually by pressing a button on the left side of the case.

2. 16,000,000-hertz electronic oscillator. This provides EMC’s reference timing rate. The performance of the balance of EMC (4hz) is compared against this pulsing oscillator to obtain the most accurate measurement.

3. An integrated circuit, determines the difference between the timing rate of the movement and that of the reference oscillator. Each microsecond difference between the two values is expressed as a gain or loss of a second per day of the timing rate. A variation of just 0.0000014 of a second per half-vibration translates as a variation of a second per day.

4. Manual-winding generator. EMC’s monitoring unit (the optical sensor and the integrated circuit) is powered by a micro-generator made by the Swiss company Maxon.

The ARCAP balance wheel

The balance wheel is made of ARCAP, an alloy selected for its non-magnetic and anti-corrosion properties. The balance was designed to optimise data from the optical sensor positioned above the wheel (shown in the previous image).

After the button on the side of the case has been pushed and the reading taken of the rate of the movement ie, gaining or losing ‘X’ seconds per day, the below image illustrates the mechanical system to adjust the rate.

A is turned, clockwise or anti-clockwise, below it F is a fine tuning scale that shows the direction of the regulation + or -

B is the underside of A that in turn sits on top of C, connecting the outside of the case with the inside mechanism, through rubber seals ensuring the watch is water resistant.

C when turned rotates the lower snail shaped cam that is connected to D, a lever that crosses the movement, and is a friction fit on E the regulating index. The regulating index adjusts the effective length of the balance spring altering its rate. The longer the balance spring the slower the watch runs, the short the balance spring the faster the rate.

A close up of the snail shaped cam regulation assembly.

A close up of the snail shaped cam dismantled.

The structure and execution of the regulating system is solid, strong and easily adjusted.

The case is complex in design. All timepieces that deviate away from traditional watch design increase not only the complexity of production but also the ability to ensure they remain water-resistant. Not only with the question of irregular form but with the number of elements in a case that need to include additional seals. Here, there are large sections that secure the capacitor, generator, regulating screw and the testing pusher, all that need custom-made seals to ensure the overall water resistance. In addition, the form of the sapphires must be perfectly aligned to the irregular shape of the case.

Rear access to the generator.

The capacitor port opened and the capacitor removed.

The circuit board unscrewed and slightly lifted showing the normally hidden cables.

The cables now detached from the circuit board. The cables are all held in place on the circuit boards inside of pillars and fastened by screws.

The stem removed in order to release the movement from the case.

Recto-verso of the circuit board.

The movement removed from the case with cables still in place.

Diagram illustrating the optical sensor

The green balance wheel is driven by the Swiss lever escapement underneath. The red sensor reads the frequency of the pulsing balance wheel and compares it against the internal electronic brain that in turn activates the rate indication on the dial.

The electronics for the start button (left) and the optical sensor (right) removed.

The majority of the electronics removed leaving the mechanical movement.

The principle case components.

The octagonal movement sitting next to the irregular shaped case.

The power-reserve indicator.

4HZ frequency of the balance assembly compared against the 16MHZ of the electronic circuitry.

The red dial illustrates the amplitude of the balance and the precision of the timing rate. The hand is hidden under the minute chapter ring until the button on the side of the case is pushed for 3 seconds then it appears.

The green numbers are printed in Super-LumiNova® onto a turning seconds disk.

The main dial removed.

The dial is cut by CNC machining and made in the same way as conventional movement components before being decorated, coated and printed.

All printing on the hands and disc are with Super-LumiNova®

Below, the main plate is the largest of the three layers and sits in the centre. The upper level is a combination of the bridges that hold the going train in place. The highest standing elements are the upper barrel and the balance cocks.

Recto-verso of the movement

Under dial work

Rear view (seen through the case back)

The fine tuning mechanism dismantled. As the snail shaped cam is turned a pinion hidden under the cam turns the gold coloured wheel still in place that carries the small grey coloured hand.

The balance wheel and cock assembly with the extended index lever that stretches to the fine tuning section of the movement.

The exterior square cut out in the balance wheel is the datum point for the optical sensor. The overall design for the wheel with the inner cutouts was deliberately designed to maintain isochronism whilst resembling an early cassette reel.

Developing a new balance wheel that was both precise from a mechanical and isochronic point of view and could be used in conjunction with the measuring functionality of the optic sensor required over 6 months of development.

The balance wheel assembly and the fine tuning components removed.

The barrel cock removed allowing access to the upper barrel.

Barrel design

Power is provided to the going train by two mainspring barrels vertically aligned in series, mounted on a single arbour. These 2 barrels provide an 80-hour power reserve.

The upper barrel removed.

The upper crown wheel cover removed. The surface of this piece aligns with the upper face of the barrel (now removed) to accentuate the continuity in the design of the movement. Underneath it is the upper crown wheel that meshes with the ratchet wheel that in turn winds the arbour with the two barrels that contain the mainsprings powering the watch.

The balance wheel hack/brake activated when the winding crown is placed into setting.

Winding position

Setting position

The escape wheel cock removed.

The large train bridge removed revealing the barrel and the going train.

The largest bridge of the movement, finished with Geneva stripes. The width of the Geneva stripes were calculated to ensure a uniform number of stripes that don’t overhang/cross the movement.

View of the movement usually hidden under the dial. The power reserve wheel train is to the left.

The bridge holding down the power reserve train removed.

The large bridge supporting the last of the electronic elements as well as part of the power reserve train removed, revealing the motion work (the wheels that support the minute and hour hands) and the setting mechanism.

Recto-verso of the central main plate.

Summary

The URWERK EMC crosses over from a solid mechanical watch with both an original design, to be the first watch that incorporates the means to electronically measure the rate of the movement. The overall mechanical/instrument feel of the movement represents high-end watchmaking through the use of decorative finishing such as Geneva stripes and flat mirror-finished screws.

The EMC is a fully mechanical watch that does not require the electronic side of its construction to function. The electronics provide a means by which the user can verify the rate of the watch, and then manually adjust it without opening the case. Conventionally, a watchmaker or technician would be employed with an external measuring device (Witchi), to measure the rate and then make the adjustment to correct the timing of the watch.

GALLERY

In the grid below are both images used in the description of this page plus more. Please click on the image to enlarge and see in full.

To learn more about URWERK