The Reason

Following the crisis caused by the quartz watch during the late 60's and 70's, when traditional watchmaking was re-born, 20 pocket watches based on the original Girard-Perregaux Tourbillon with Three Gold Bridges design were launched in 1980. Each one took 1500 hours of to complete, below is the first one to be finished.

The original pocket watch Tourbillon with Three Gold Bridges, the watch design Girard-Perregaux is historically most famous for, was designed and made in the 1860s.

“This pocket watch, as mentioned above was made over 40 years ago. The one hundred+ images shown in this deconstruction have often had the background removed as is the standard approach on this site to emphasize the subjects photographed. During the life of the watch the case has slightly tarnished with age and there are micro-scratches, both on the movement from previous services and on the case from use. These marks that are part of the life of the watch”- The Naked Watchmaker

Recto-verso of the 18k yellow gold pocket watch case with engine-turning/guilloché decoration.

The central shield designed for personalisation.

Approximately 60mm in diameter

Heavy/solid 3 piece hinges for both the front cover and case back.

The front cover ‘pops’ open when the button in the winding crown is pushed. The case back is opened using a thumb-nail under the additional material protruding from the case back (shown below).

To set the time there is a small steel lever (at 4 o’clock), hidden when the case cover is closed. Sliding the lever pushes the winding mechanism into hand setting position.

The lever in winding position.

The lever in setting position.

When the cover is snapped closed, if the steel lever has not been returned manually, into winding position, the lever is pushed into its default winding position by the inner part of the case cover.

The cover is held closed by the steel lever set at 3 o’clock next to the bezel. The button set into the winding crown pushes against this lever from the inside of the case.

The case comprises of the hinged front and back covers plus an additional hinged inner dust cover.

Once the dust cover is open, the movement is protected by a bezel with thin glass.

All of the flat sections of the case are around the case backs and cover are circular grained, the bezels and domed central section are polished.

Hand engraved on the inner dust cover is ‘CHRONOMETRE TOURBILLON, Girard-Perregaux & Chaux-de-Fonds’.

The dust cover is polished before and after the hand engraving was made.

The inside of the case back is also engine turned.

On the inside of the case back are the company brand and stamp, as well as the hallmarks for the 18k gold.

The bezel free from the case centre.

The bezel clips on to the case centre and is removed with a case knife. The glass pops into the bezel prior to the bezel being pushed in place and the complete assembly is held by the mechanical pressure of the assembly clipping together.

The dial and hands removed from the movement.

Both the hands and dial are friction fitted onto the watch.

The decorative Louis XV hands are made in 18k yellow gold.

With the dial removed the steel winding wheels can be seen.

The rose coloured wheels in the centre are the motion work that drive the hands.

The enamel dial is held onto the movement by the brass skirt clipped around its circumference.

The dial is made in three pieces, the principle white hour section, seconds subsidiary dial and brass skirt.

The dial is enamelled on both sides to maintain an even tension through out the dial and the subsidiary dial is soft lead soldered in position.

The inner bezel and glass removed.

The jewels are set into gold chatons that are in turn held in place with screws that act on polished steel rings holding the chatons (gold bush) in position.

Centre wheel pivot bearing.

Barrel arbour pivot bearing.

Tourbillon cage pivot bearing.

In total there are 16 jewels.

Removing the movement from the case.

The steel screw to the right of the gold arrow shaped bridge holds in place a lever securing the stem in place.

One of the two movement clamps.

The movement still with its movement ring surrounding it, removed from the case.

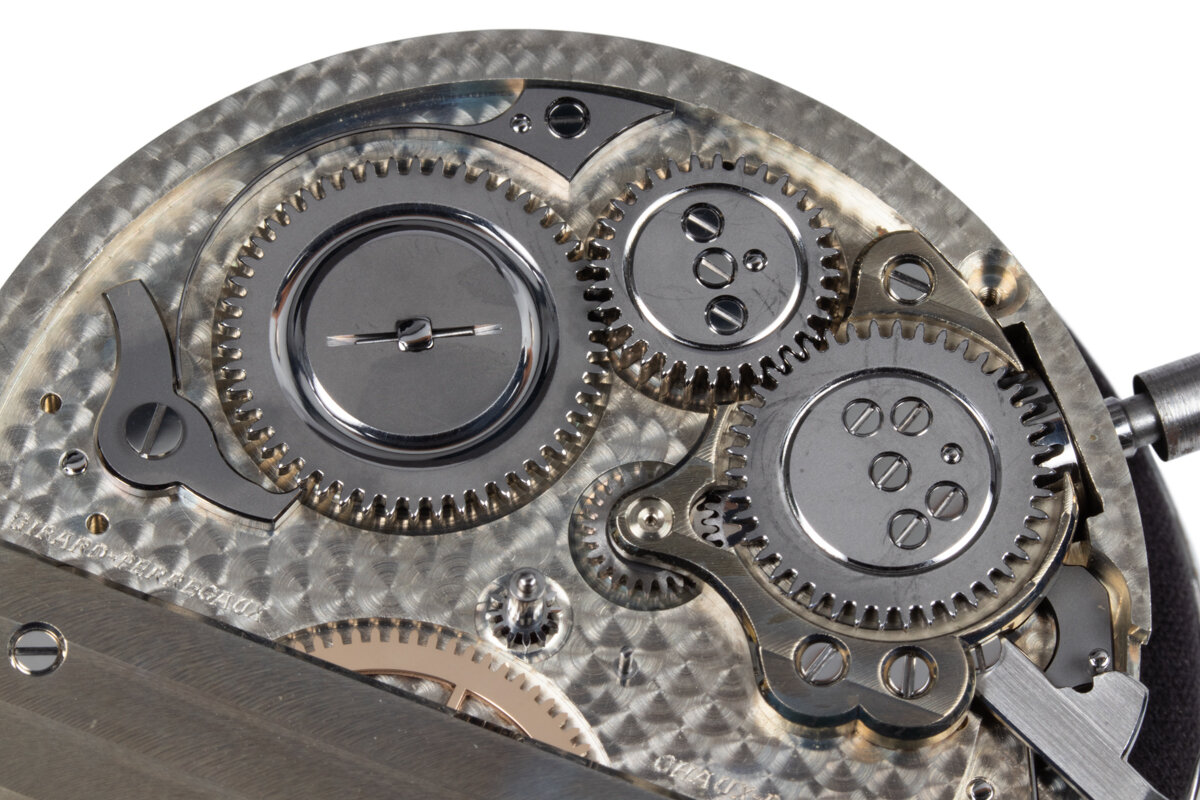

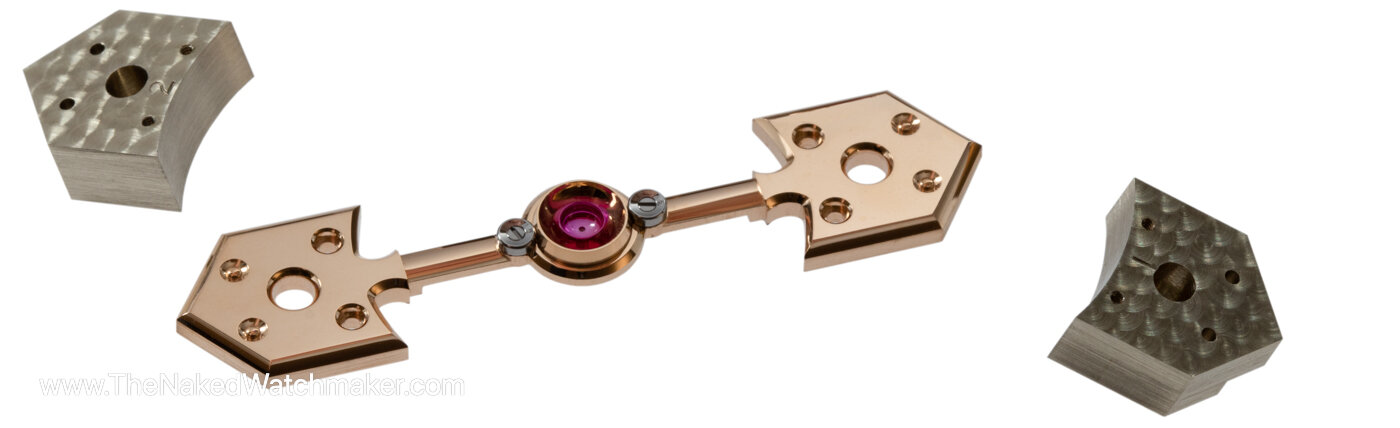

The top sections of the bridges are made in 18k rose gold, the pillars and main-plate from German silver.

The movement ring removed.

The two screws to the left hold the ring in position, laterally traversing the ring and locking into the main-plate of the movement.

The two movement clamps free from the movement. (Beautifully angled and decorated).

The watch partially disassembled.

The locking lever for the stem.

The stems locking lever fixed in place.

The stems locking lever loosened to remove the stem.

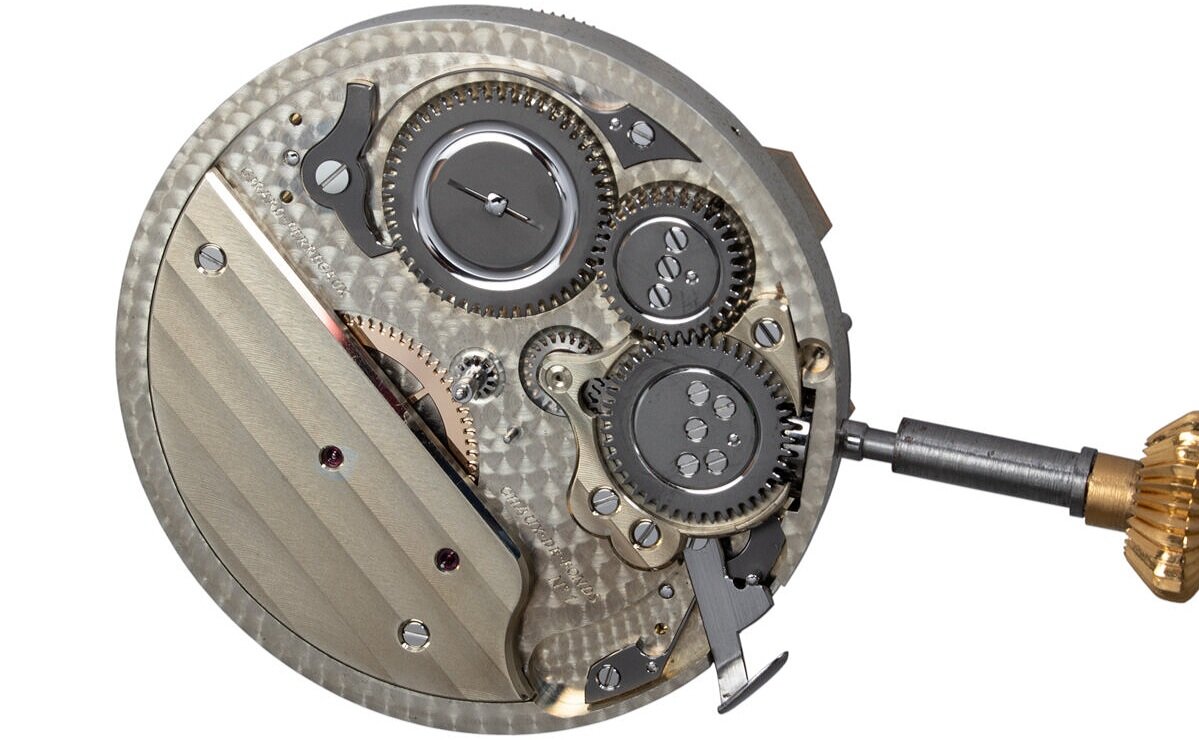

Movement diameter 45mm, thickness 10mm.

The centre, third, fixed, and escape wheel are made in gold.

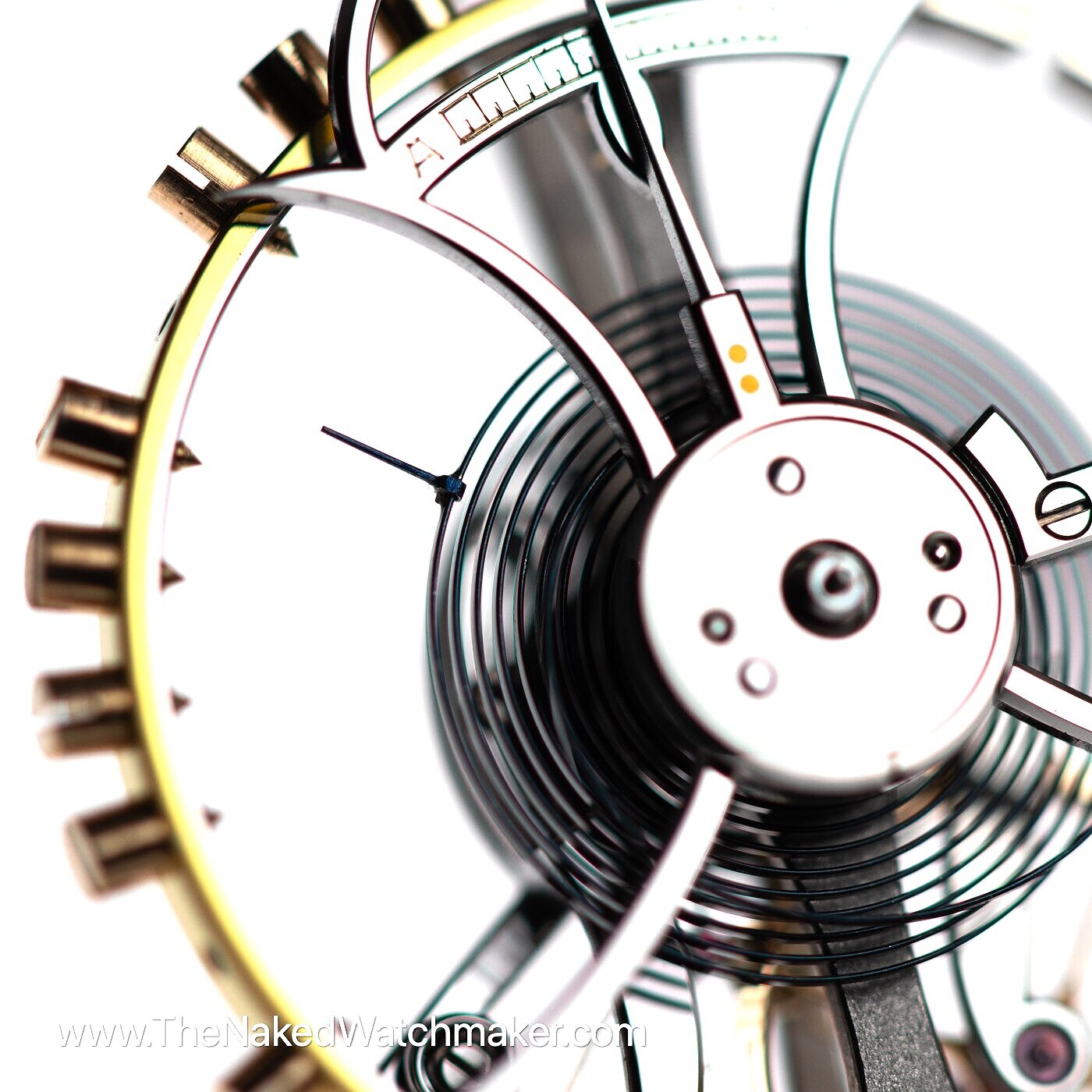

The Tourbillon cage and its bridge.

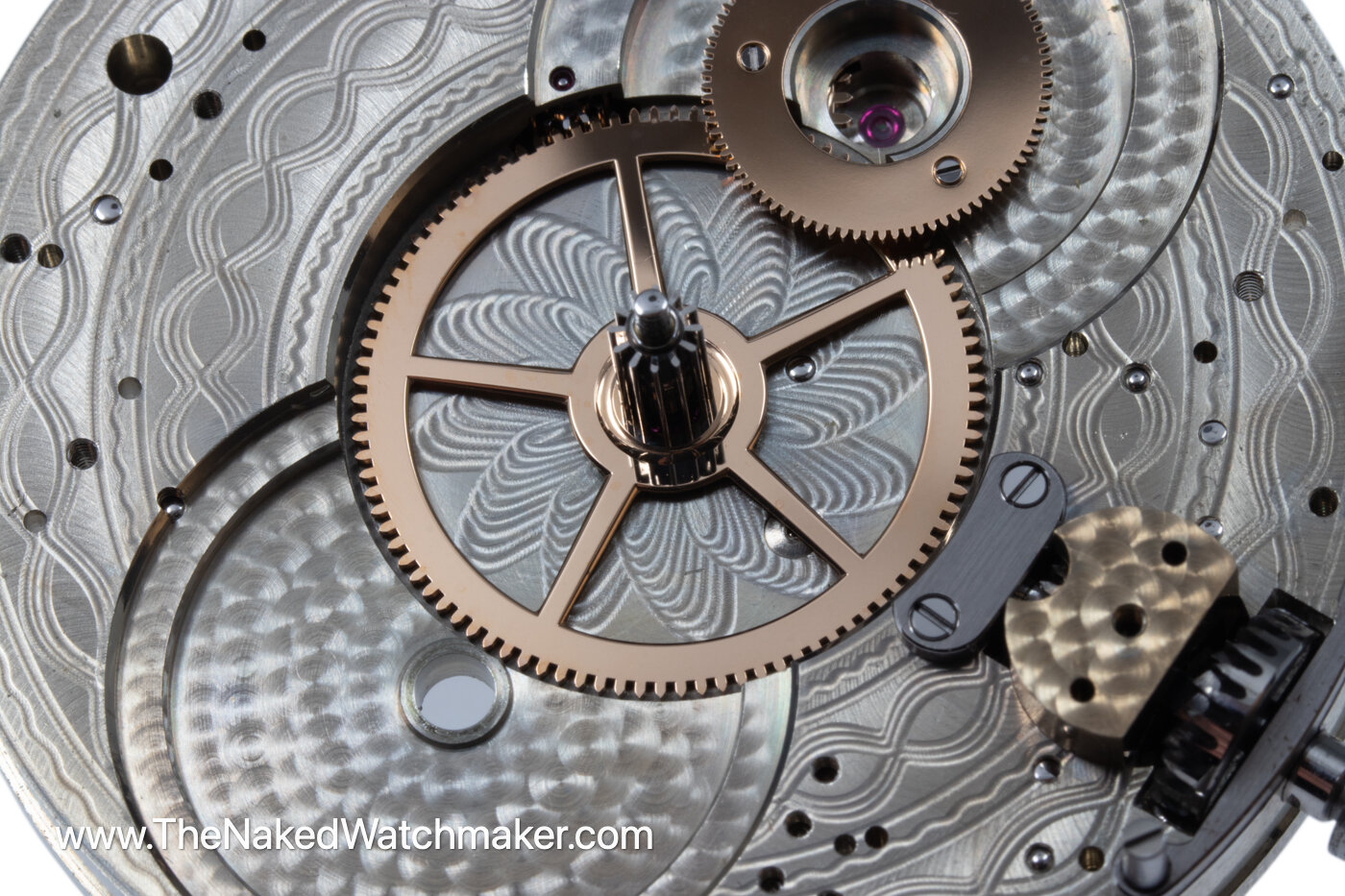

The engine turned decoration on the main-plate is unusual, even today. It accentuates the form and polished surfaces of the 3 bridges.

The Tourbillon cage still in place with its bridge removed.

The Tourbillon cage removed showing the gold fixed wheel hidden below it in the main-plate. This wheel meshes with the escape-wheel pinion as the cage turns.

The Tourbillon cage consists of 80 components and weighs approximately 1,3 grams.

Instead of a traditional Swiss anchor escapement a pivoted detent escapement was used.

Both the escape wheel and the long straight detent spring are made from the same gold.

The detent escapement was traditionally used in marine chronometers. It is not self-starting, such as the Swiss or English lever escapements and requires a gentle rotational motion of the movement to start the watch, but creates less friction than conventional escapements.

The balance spring has an over-coil with an amplitude limiting device incorporated into it (the radially protruding steel piece attached to the outer coil). Edouard Phillips theory, 1859.

The detent escapement was invented by Pierre Le Roy (1717-1785)

The large gold screw to the left of the steel pillar with a polished head, acts as a weight to help poise the cage and assure its equilibrium.

In the centre of the image is the index, (partly) used to adjust the time keeping. The engaving A-advance R-retard. (Fast and Slow).

The Guillaume balance wheel was invented by Charles Edouard Guillaume (1862-1938).

The Guillaume balance wheel is a split bi-metallic type, with gold timing screws. Designed to compensate for the timing variations caused by temperature on the carbon-steel balance spring.

The Tourbillon cage partly dismantled.

Full view of the underside of the balance and upper cage bridge.

Close up of the large impulse jewel that receives energy from the escape wheel, and the small unlocking jewel that acts upon the long, thin, gold detent spring.

The lower part of the Tourbillon cage with the balance removed.

The surfaces and angles are mirror finished.

The lower part of the Tourbillon cage showing the pinion that drives it, and the extended pivot upon which the small seconds hand is friction fitted.

All steel components are made from hardened carbon steel.

The centre wheel bridge removed.

The underside of the bridge showing the milled out sections for the winding system.

The barrel bridge removed.

The barrel provides a power reserve of 36 hours. The mainspring never fully unwinds, or can be forced when winding due to the Geneva stop-work that is fixed onto the barrel cap.

The Geneva stop-work allows 4 turns of the barrel arbor each running for 8 hours providing the 32 hour power reserve.

The steel ratchet wheel slides onto the square of the barrel arbor (on the Geneva stop work side) and is locked in position by a steel pin.

The barrel removed leaving the centre and fixed wheel in place.

The gold wheels are both hand angled and, as with their flat surfaces, polished.

The construction design and execution is solid and made to endure.

The three bridges, the lower one with its German pillars removed.

The Tourbillon bridge with its two pillars.

Each pillar is held in place by 2 small steel screws and positioned by two guiding pins. Then, on each arrow head a single large screw holds the bridge onto the main-plate.

Full view of the under dial mechanism.

The right angled gearing that transfers force from the stem to the barrel/mainspring or setting, depending on mode.

In addition to the angling on the visible wheels through the case back, the steel winding wheels also have polished angles.

The satin finish on the steel is made with a carborundum paste on a hard flat surface manually.

The ratchet wheel (to the left) held on to the barrel arbor square by a steel pin. To the ratchet wheel’s left is the click that prevents the ratchet wheel from unwinding.

The large steel lever that pushes the setting lever into setting position. Here it is in winding position. It acts on the pin of the setting lever that in turn positions the sliding clutch.

The small pinion meshes with the minute wheel (removed) to adjust the hands.

A small but nice feature is the internal angle on the upper bridge below the two screws. This is usually never seen and the additional detail creates more work and time to execute but the result is a reflection of a quality execution. The Chaux-de-Fonds No.1 engraving is made by hand.

A mix of decoration; satin finished steel wheels and click with polished angles. The main-plate manually spotted, the higher bridge (in relation to depth) with Geneva stripes and angling. The gold wheel mirror finished.

Summary

The original Tourbillon with Three Gold Bridges was and became an iconic design in watchmaking that helped define many future Girard-Perregaux timepieces. The watch shown on this page is a faithful reproduction of one of those original pieces. It was made to endure, and record time accurately. The construction is balanced, solid, beautifully decorated and classically executed in its proportions. With care and respect, the kind of watch that if used daily would survive for hundreds of years to come.

GALLERY

In the grid below are both images used in the description of this page, plus more. Please click on the image to enlarge and see in full.

To learn more about Girard-Perregaux