In horology, a wheel train (or just train) is the gear train of a mechanical watch or clock. Although the term is used for other types of gear trains, the long history of mechanical timepieces has created a traditional terminology for their gear trains which is not used in other applications of gears. -Wikipedia-

The machine below is loaded with different diameters and material bars in the cylinders to the right of the image depending on what type of wheel, pinion or part will be manufactured. In the foreground the bars are fed through and the multiple tools either side of the collet in the centre then cut the material. The same process as is used in the previous section on profile turning. These machines can produce the blanks for wheels and pinions which are then cut later in other machines as well as pins, screws, canons etc.

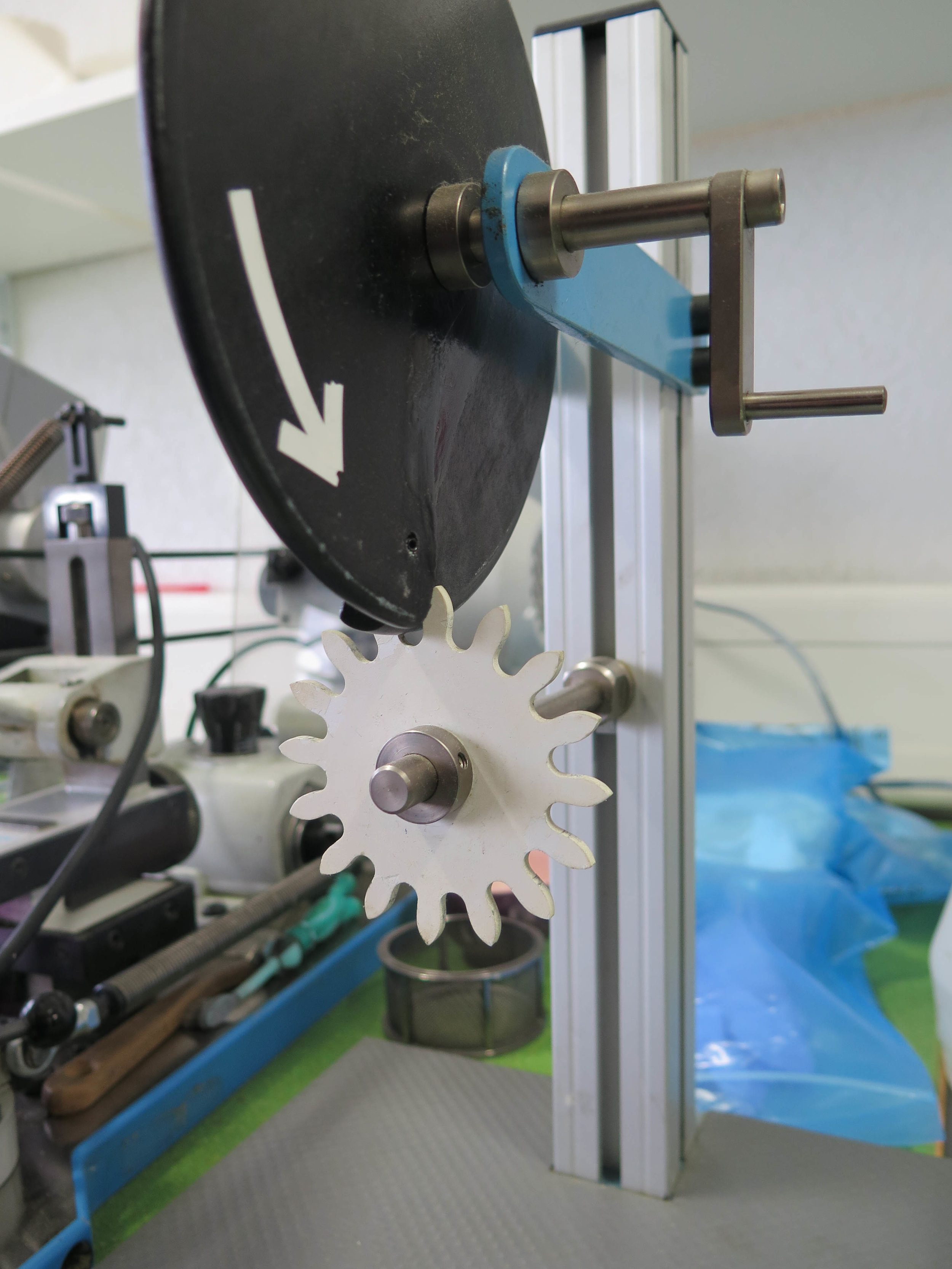

A simple jig used to hold a single blank at a time to be machined.

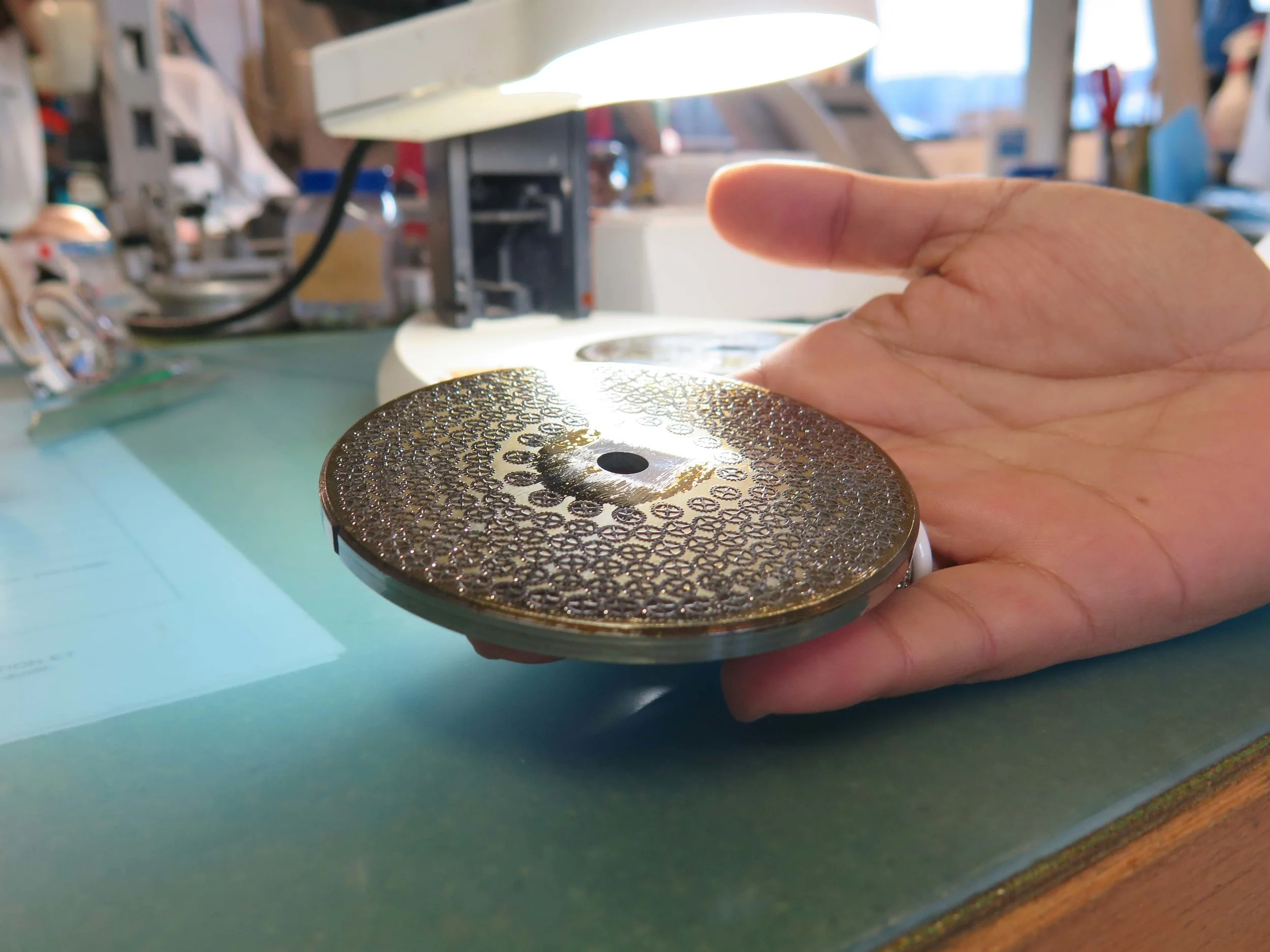

Brass blank disks machined in the machine below, gold plated and about to have teeth cut into them by generation.

The blanks below, to the left prepared in place, to the right being machined by generation.

The machined below is used to sharpened tungsten carbide tools than have become slightly worn.

Hobbing machines for cutting the teeth on wheels and pinions.

Various carbon steel parts are placed in the below furnace, heated red hot and automatically plunged into oil to harden them. An early system to effectively harden carbon steel but still used today.

Wooden disks loaded with compounds used to polish pinion teeth, in the picture below right the disk is levered open by a small piece of wood which allows the disk to index each tooth on the pinion so as to polish all the teeth as the wheel rotates.

A model showing the above operation.

A brass band which has just left a stamping press, the disks are pushed out of the strip manually to avoid any deformation.

The central holes of the disk are then manually checked to one thousandth of a millimetre.

The disks are then circular grained.

Another machine used for decorating the wheels using 3m abrasive papers.

Stamp angling wheel blanks.

Before and after

Below are images from the workshop that specialises in burnishing the pivots and shoulders of the pinions and balance staffs.

Burnishing shoulders on a balance staff.

The unfinished balance staffs.

Checking the pinion as the pivots are being burnished.

Polishing the escape wheels.

Assembly of the escape wheel and pinion.