The Reason

An inhouse, classically executed mono-pusher chronograph with Tourbillon and power-reserve. Combining innovative mechanics with traditional spirit.

Functions

Hours, Minutes, Tourbillon, Chronograph, power reserve, small seconds on Tourbillon carriage, 45-minute chronograph counter.

Certification: Hallmark of Geneva

Technical Specifications

Movement reference 3200. Manual-winding. Movement diameter 32.8 mm, thickness 6.7 mm. Number of parts 292. Number of jewels 39. Power-reserve 65 hours. Frequency 18000 v.p.h. (2.5 Hz). Case material 18K 5N pink gold. Diameter 42.5 mm. Thickness 11.7 mm. Front and back glasses made from sapphire. Water-resistance 3 bar.

The case back removed from the case centre. The serrated edge makes (the initial application), and final removal easier after the case back has been initially loosened by a 7 pronged key.

In between the movement and the case is the movement ring that acts as a spacer between the two parts.

The surface of the bridges are decorated with Geneva stripes, all screw heads are polished and angled, levers, springs and hammers are also angled, flat and side surfaces straight grained.

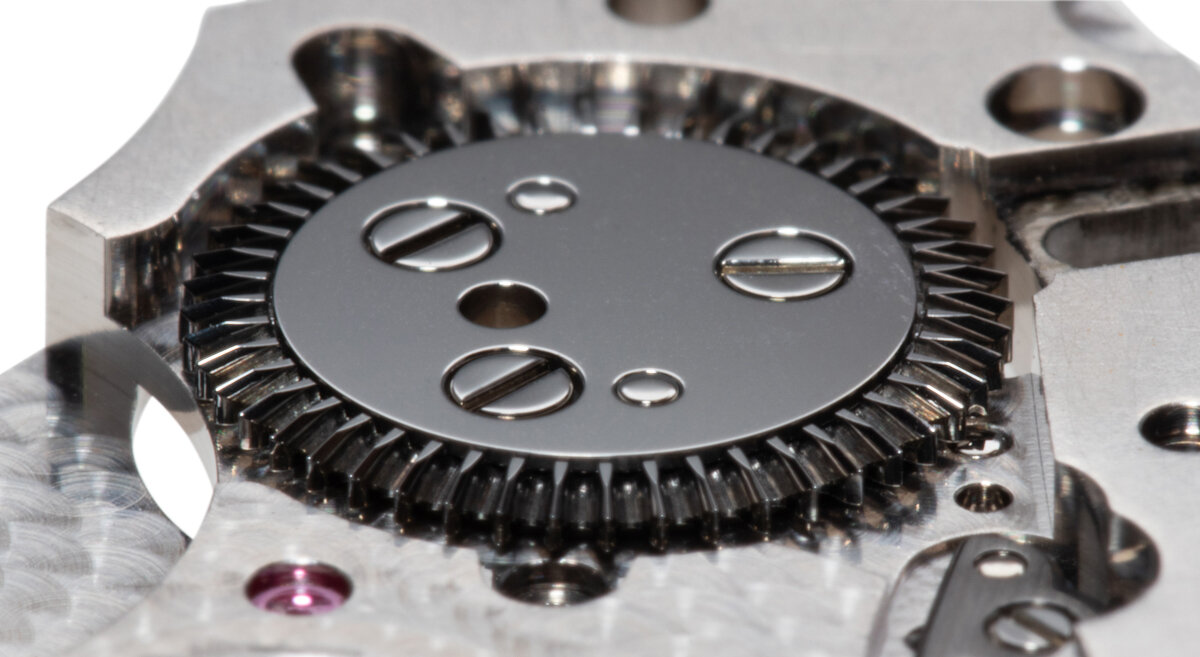

The column wheel central section is machined in the form of the Maltese cross Vacheron Constantin logo. As the button, set into the winding crown is pushed, the column wheel turns moving all of the levers resting upon it: position 1 start, 2 stop, 3 return to zero.

The movement is held in the movement ring with 2 large screws. The movement ring is fixed to inner case back with 3 sets of casing clamps and screws.

The movement removed from the case with the movement ring still in place.

The red gold, water resistant winding crown with stem.

The black seal on the lower section of the winding crown acts against the inner polished steel surface of the crown tube, making the winding crown water resistant.

All of the hands except for the steel chronograph seconds hand are made from gold.

The dial removed from the movement.

The hour indexes are riveted in place from the back of the dial.

The underdial view of the movement.

The gearing at the bottom of the calibre associates with the power-reserve indicator.

The Vacheron Constantin Maltese cross logo is used in the design of the upper cage bridge of the Tourbillon. The bridge is made from hardened and tempered steel.

Locked between a pillar and the Tourbillon cage bridge (shown here at 5 o’clock) is a small, black anodised steel triangular piece, this provides indication for the seconds on the seconds chapter ring.

The setting mechanism. The basic design is simple, strong and classic in form. Hand decorated.

The yellow wheel with large polished headed pin carries the power reserve hand though its extended pivot.

All of the wheels, levers and surfaces throughout the calibre are decorated regardless of their location, visible or not visible, once assembled. This is a characteristic of higher level timepieces, mentioned many times before on this site, but worth repeating to reinforce one of the elements that differentiates the positioning of different horological products.

The Tourbillon cage, pivots in jewelled holes. The upper jewel is set into the a gold ‘chaton’ (bush). The gold chaton is a traditional way to hold a jewel into a hard steel bridge without the risk of the jewel being damaged when it is pushed into position and adjusted.

The bridge crossing the Tourbillon cage is only viewed through the open aperture of the dial. The lower sections including the screws which lock the bridge in place are hidden under the dial.

The upper Tourbillon bridge removed in preparation for removing the cage from the movement.

There are exceptions to every rule in watchmaking, one of the general ones is to dismantle the most delicate elements when taking a watch apart, the Tourbillon cage being one of them.

The Tourbillon cage and upper bridge removed from the movement.

The cage is driven by a pinion meshing with the teeth on the outer diameter of the large wheel that forms the base of the Tourbillon cage.

Recto-verso of the cage.

The balance spring has a hand-lifted over coil, terminal curve. The large gold segment weight, hand engraved with VC is to help with the equilibrium of the cage, poising the weight of the escapement and its bridge on the opposing side.

The bridge holding the escapement in place is usually fixed on the inside of the cage. In this design, it slides onto the cage from the underside, but the screws holding it are tightened from inside the cage.

The cage partially dismantled.

The gold sector is held in place by two of the pillars, screwed from the underside. As with the upper Tourbillon bridge the jewels are held in gold chatons. The cage pivots are turned on plates that are positioned onto the cage and held by two screws either side.

The small shield to the right of the Vacheron Constantin name on the upper bridge is the official Geneva hallmark. The characteristics contributing to the Hallmark of Geneva are characterised by both technical and decorative stipulations as well as their location of execution, ie Geneva.

The chronograph mechanism consists of a mix of hammers, to return the chronograph seconds and minute hands back to zero, selection levers, brakes, drive and column wheels.

The last wheel on the left hand side of the image is the upper 4th wheel, it is driven onto the lower 4th wheel extended upper pivot. This lower wheel is part of the going train. This upper wheel drives the chronograph mechanism.

In the very centre of the image is the steel pinion that drives the minute recorder. In most conventional chronographs the minute recorder ‘jumps’ minutes as the chronograph seconds hand crosses from 59 seconds. Here, the minute recorder constantly moves as the chronograph functions, the steel pinion driving the lower steel wheel. The upper gold coloured wheel is acted upon only by the brake when the chronograph has been indexed into stop position, preventing the wheel from moving.

The Tourbillon cage removed. The fixed gold coloured wheel at the bottom of the movement drives the escape-wheel pinion, in turn transmitting energy through the steel escape-wheel to the Swiss lever, then impulsing the balance, resulting in the Tourbillon cage turning.

The train of chronograph wheels.

Left to right; upper fourth wheel (constantly turning), coupling clutch wheels (on two layers in the coupling clutch), chronograph seconds wheel, small intermediate pinion driving the last wheel to the right, the minute recorder wheel.

The coupling clutch removed from the chronograph. In conventional chronographs, there is only a single wheel in this assembly. The role of the assembly is to drive the chronograph mechanism when requested by engaging with the central chronograph wheel. Then, when the pusher on the case is again pressed, the wheel in the coupling clutch disengages with the chronograph seconds wheel stopping it from being driven. Here, the upper gold-coloured wheel is in constant contact with the upper fourth wheel constant turning, however, whereas on most systems the same wheel will mesh with the chronograph seconds wheel, in this design a lower steel wheel with much finer teeth does the work.

The reason for this approach of a double layer of wheels is to ensure the most smooth ‘start’ of the chronograph as possible, avoiding the second’s hand from jumping when the teeth first engage. This is one of the steps forward in precision development of a lateral coupling clutch system.

In order to remove the main operating lever shown at the bottom of the movement, the coupling clutch and the pieces to the right of the image need to be removed.

The operating-lever removed.

The oval hole at the end of the operating lever houses a strong pivot of another component (shown directly below) that is pushed by the lower section of the winding crown, activating the chronograph.

The large pivot sits in the oval of the operating lever, the ‘U’ shaped section sits around the base of the winding crown.

The upper bridge removed revealing the hammers acting against the heart shaped cams which return to zero the chronograph seconds and minute recorder wheels.

The hammer in the centre of the image zero’s the chronograph seconds wheel. The small finger piece at its base has fallen between the columns on the column wheel. When the operating lever is activated the column wheel will turn, lifting the finger of this hammer and in turn the minute wheel recorder hammer to its left, both will be pushed to one side allowing the chronograph to operate.

The minute recorder and chronograph seconds wheels with the associate hammers.

The same double layer approach used on the coupling clutch wheels has been used here on the minute recorder wheel.

The two steel pieces below the column wheel are the brakes for the chronograph seconds and minute recorder wheels.

The lower gold coloured wheel to the left is the upper fourth wheel that drives the now removed coupling clutch.

The upper fourth wheel removed from its extended pivot on the lower fourth wheel.

3200/1 Calibre reference

The lower Tourbillon bridge removed in which the Tourbillon and the pinion that drive the Tourbillon pivot.

The pinion that drives the Tourbillon, to its right the centre wheel.

The principle chronograph bridge removed revealing the barrel and going train.

The double wheel assembly below links the barrel to the power reserve indicator mechanism.

The double-wheel assembly (mobile) below, drives the power transmitted from the barrel through the thickness of the movement to the power reserve indicator train. In one sense the power reserve indication hand is moved to ‘wound’, manually directly with a link to the barrel ratchet wheel intermediate wheels. Then as the watch unwinds alternative elements in the same gearing cause the hand to run down as the watch functions.

The teeth of the pinion in the centre are cut at 45 degrees.

As the column wheel is removed (below), the two brakes relax into space normally occupied by it. The large lever above the centre is the column wheel indexing spring, it is the strongest spring in the movement.

The pieces that constitute the column wheel.

The column wheel turns on the steel ring to its right. The screw enters the Maltese cross ‘nut’, from underneath holding the assembly together.

The underside of the principle train bridge.

To the left is the ‘click’, that prevents the ratchet wheel from unwinding as the mainspring is being manually wound up. To the right are two of the wheels that make up the power reserve indication.

The screw in the image secures the setting lever in place (hidden on the other side) that locks the stem from being removed. To its right is the winding pinion and sliding clutch. The sliding clutch moves left and right between setting and winding depending on the position of the winding crown. At present it is in winding position meshing with the winding pinion to its left.

The winding pinion is a standard component found in every mechanical wristwatch (manual or automatic). What makes this one unusual is linked with the upper crown wheel shown below. 99% of the gearing meshing between the upper crown wheel and the winding pinion mesh at 90 degrees. In this execution, the gearing is set at 45 degrees, increasing the smoothness of function as the mainspring is wound.

Upper crown wheel.

All of the functional surfaces of the teeth are polished to further reduce the friction when winding the watch.

The barrel meshes with the centre wheel (or second wheel) that in turn meshes with the third, fourth (with extended pivot to carry the upper fourth wheel and drive the chronograph) wheels, then the pinion that drives the Tourbillon cage.

The small pinion that is meshing with the barrel at the top of the image causes the power reserve indication to run down as the watch is ticking.

Recto-verso of the main-plate, well dismantled.

To the right the setting mechanism. At the bottom the final mobiles in the power reserve train.

Only the centre wheel remains in place.

The power reserve pieces shown above dismantled.

The clutch wheel (shown on the next image as well as here) is produced using a form of UV-LIGA technology. The wheel, teeth, arms and clutch spring are all produced in a single piece.

A close up of the wheel in the previous image to the bottom left.

This wheel has a built in clutch mechanism that allows the pinion carrying the power reserve indicator hand to slip when it is fully wound showing a fixed fully wound position. This facilitates the set up of the watch when first assembled and helps compensate for the slight difference in lengths of mainsprings.

Summary

This in-house, mono-pusher chronograph with Tourbillon and power-reserve, combines innovative mechanics with a traditional spirit.

At first glance, the overall construction of the movement is synonymous with Vacheron Constantin's level of quality, seen in the other deconstructions found on this site.

The watch follows a classic design, is hand finished and meets the Geneva Hallmark requirements. The design is robust on a practical standpoint as well as branding. The Vacheron Constantin Maltese cross logo forms the Tourbillon bridge's design, the cross can also be found partially visible under the coupling clutch and minute recorder wheels, as well as the central section of the column wheel.

The use of additional layers of wheels in the coupling clutch and minute recorder assemblies to ensure smoother functionality, as well as simplifying the initial setting up of the chronograph by the watchmaker, is an innovative step forward in chronograph design.

The design of the Tourbillon cage is classical, using a hand lifted over-coil balance spring, and balance wheel with timing screws. Resulting in a free-sprung balance (with no index adjustment). But unusually, the escape-wheel and anchor bridge is placed under the cage main-plate (which also doubles as the drive wheel for the cage). This results in positioning the balance wheel closer to the centre of gravity of the cage, and allows for a particularily clean and direct meshing and transmission of power with the pinion that drives it.

From a watchmakers perspective when dismantling and re-assembling the watch, it becomes clear that the movement has been designed for longevity and precision.

GALLERY

In the grid below are both images used in the description of this page, plus more. Please click on the image to enlarge and see in full.

To learn more about Vacheron Constantin