The Phoenix Collaboration between Schwarz Etienne & Les Ateliers Blandenier

Schwarz Etienne is an independent brand and manufacture based in La Chaux des Fonds, Switzerland, producing small numbers of simple and complicated timepieces under their own brand name as well as providing private label services under their subdivision La Division du Temps.

Les Ateliers Blandenier, was developed over 20 years ago by Christophe Blandenier, originally specialising in engraving and setting. It now has thirty craftsmen specialing in the majority of the ‘métiers d’art’ from diverse techniques of hand engraving, stone setting, enamelling (grand feu) painting, acrylic painting, ceramic painting, angling of components, damasquinage, making jewellry pieces as well as specialised CNC machining.

The project was conceived and directed by The Naked Watchmaker.

The reason for the project.

The Phoenix collaboration was a concept from The Naked Watchmaker platform. Developing a synergy between Schwarz Etienne and Les Ateliers Blandenier, to make a unique time piece that would showcase the watchmaking process of Schwarz Etienne and artisanal skills of Les Ateliers Blandenier.

The theme and explanation of the dial.

The base of the dial is made in 18ct gold and filled with enamel, the smokey blue and white effect of the enamelling is to generate the impression of a blue sky. The gold Phoenix is hand engraved and then lacquered, the subject was chosen as a representation of an element that always returns. The Phoenix then links to the quote around the dial, “Our greatest glory is not in never falling, but in rising every time we fall.” –– Confucius. (A statement in an ever-changing and challenging world). The small seconds subsidiary dial is set with pyrite stone, the name of the stone originates from the Greek "pyr" meaning fire.

The goal of the project was to integrate multiple skills into the making of a unique ‘Art-piece’ and to present them on The Naked Watchmaker in order to both share the complexity of the project and the time and people involved within such an undertaking.

Dial made by Atelier Blandenier.

Watch made by Schwarz Etienne.

The watch can be split into two parts, each containing multiple steps. The watch itself and the process of decoration of components and their assembly, partly illustrated below on this page, the second part the dial making section.

Multiple artisanal techniques that individually carry historical value combined can result in unusual effects. The depth of the blue enamel sky was selected to generate a contrasting back-drop for the applied phoenix positioned above the pyrite seconds disc, making it appear to be suspended in the sky.

Technical Specifications

The total thickness of the case 12.13mm, diameter 42mm. Made from 18ct red gold. Water resistant to 50 meters. Calibre ASE 100.00 Thickness: 5.35mm and diameter 30.40mm. Power Reserve 86 hours. Automatic winding. Frequency 3Hz (21,600Alt/h).

The selection of the Schwarz Etienne ‘Roma’ case was made in order to have a classic understated design that would highlight the aesthetics of the dial and movement.

Making the dial

Step one was to define the design upon which the dial would be made. This process spanned approximately 2 months starting in late April of 2020. There were multiple designs and variations made before the final one was selected. During this process, the specific techniques to be implemented were chosen, elements such as the pyrite were added and the text was simplified.

Deborah, one of the enamelers, also an artist, designed the Phoenix and was involved in the enamelling process.

The early designs contained batons and indexes that were rejected in order to emphasise the organic nature of the enamelling, engraved gold phoenix and pyrite.

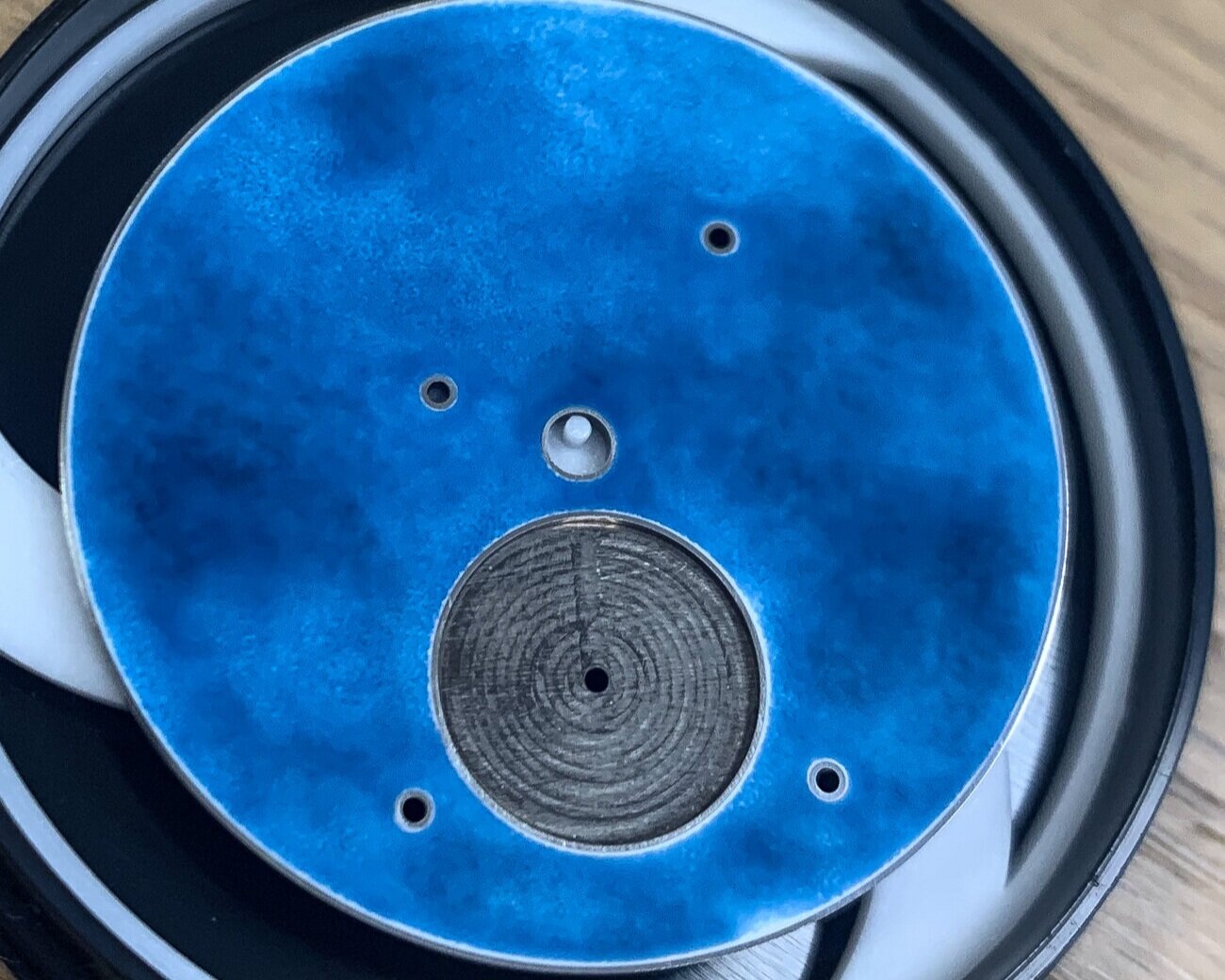

The base-plate for the dial.

The base plate was made in 18k gold. To be enamelled it required having sufficient space on both sides to have enamel added to assure equivalent tensions within the dial, to avoid the future possibility that it might deform and crack.

This image shows the CAD (computer aided design) of the base plate. The green surface will be for the enamel, the central tube allows for the canon pinion and hour wheel to pass upon which the hands are pushed. The larger circular grey section is for the pyrite and the small seconds hand. The 4 small tubes will eventually receive the pins on the back of the phoenix holding it into position.

The Willemin CNC machine used to machine the base plate of the dial. The dial shown was a trial, cut in brass to verify the tolerances and result, once validated the real base plate in gold was added.

Selecting the enamel.

Once the base-plate is finished the enamelling can be added. The sky effect for the dial was married in colour to the hands, but to insure the association in shades was correct the enameler made multiple trials with enamel powders that were heated in an oven to ensure the final choice was correct.

This process is always carried out by the enameler’s to ensure the final colour of the enamel is correct once it has left the oven.

The dial being heated repeatedly below in an oven at approximately 600 degrees celsius.

The oven used is specific to enamelling and can be accurately controlled to ensure the varying high temperatures needed by the enamelers are controlled.

The copper support the base-plate sits upon when in the oven, touching the dial only on its edges allowing the heat to be evenly distributed.

The door is spring loaded to allow it to be easily opened and closed multiple times during the process.

Early on in the process when only a small layer of enamel has been added. Enamel powder will be added approximately 5 times until the desired thickness and result are achieved.

The finished enamelled base-plate.

The back of the dial also enamelled and signed by Blandenier. In the majority of enamel dials, the backs are enamelled to assure an even tension throughout the dial to avoid the enamel potentially cracking over time.

Historically, even in the age of A.L.Breguet the dial maker would sign the back of the dial.

Making the Phoenix.

The design originally made by Deborah was taken and traced, so that the contour of the Phoenix could be precisely cut out by wire erosion prior to being hand-engraved.

The design of the Phoenix sitting on the base-plate with the location of the pins/feet of the bird in place coordinating them together.

The wire erosion machine used to cut out the Phoenix.

The CAD design for the contour of the Phoenix as viewed on the monitor of the machine.

The CAD design for the contour of the Phoenix as viewed on a computer prior to machining.

A partially finished cut out trial test of the phoenix in brass. Once validated the real piece was made in 18K red gold.

The remaining part of the gold plate after the phoenix was cut out.

The thickness of the gold phoenix was machined to the correct height prior to being cut out of the plate, the reason for the circular form around the bird. The three holes close to the contour of the phoenix are the access holes for the wire that cut the form out using electro erosion.

The gold phoenix is fixed onto a brass plate whilst the engraver carves the detail into the metal.

The engraver (here Christophe) working using a microscope.

Basic outlines are lazer-engraved onto the surface of the gold to facilitate replicating the original intended design for the engraving . Here the tail as not yet been touched.

The engraving of the phoenix required approximately 3 weeks of work.

Each feather is engraved separately and the texture of the surfaces added.

After the engraving was complete an acrylic painting was made on the surface to add a patina of age and increase the three dimensional effect. With out this final step much of the detail of the engraving can in essence be lost, washed out by uniformity of the material colour.

The scale of the work can here be seen when the acrylic paint is being added.

The plate of red gold used to make the Phoenix.

The off-set small seconds disc was made from pyrite.

Pyrite in its natural state.

The samples.

Cubes of pyrite were machined to identify the one that most resembled the original design.

The disc of pyrite was 2,5/10 mm in thickness and 11 mm in diameter, 5 examples were made and the choice of disc was based on the amount of detail inside of the material, some once polished were almost free of imperfections and no longer retained the organic aesthetic.

Only the beak and claws are polished.

The final dial was assembled by Dorian, who soldered the pins protruding from the back of the Phoenix in place from the rear of the dial, then fixed the pyrite into position after polishing the rim of the dial ring it sat in.

Finishing the movement

Schwarz Etienne provided the watch for the dial, a hand finished, micro-rotor in-house calibre housed in an 18k red gold 42mm Roma case.

The full process of manufacturing a high quality watch movement can be viewed here at Vaucher Manufacture Fleurier. Below is part of the process of finishing and assembly of this watch; concentrating on showing how parts are angled and followed by the assemblies.

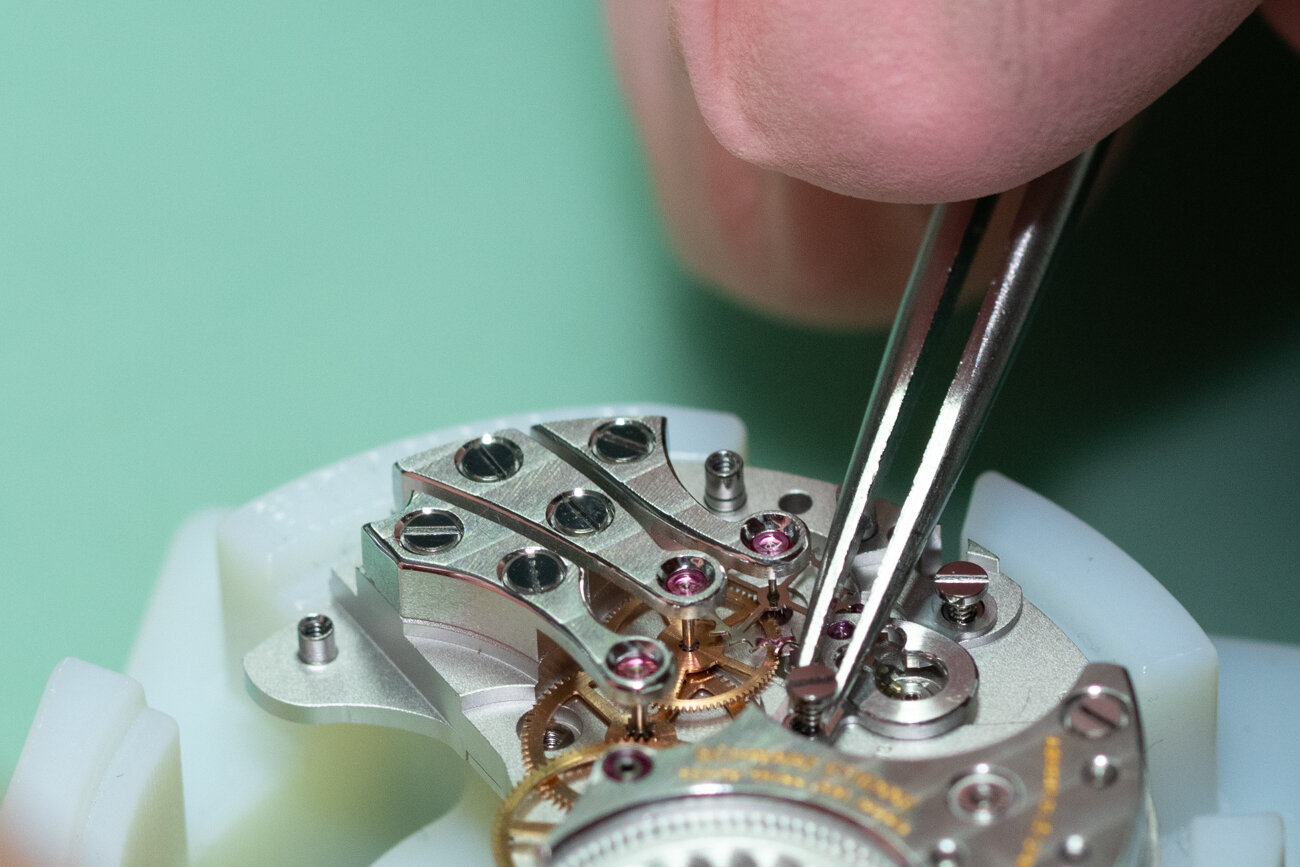

The manual process of angling, removing the sharp edge from a bridge and polishing it evenly can be executed in multiple ways. Some companies will pre-machine the angles in preparation for the final polishing, others will remove the angles manually as is shown here.

The part being decorated is often fixed to a jig to be able to make its manipulation easier.

The shapes of bridges and cocks vary, as a result a wide variety of files and laps are used that are often tailored for specific forms by the angler.

8 different polishing laps, ranging from 1 to 30 microns in grain. The 30 micron is course and used after the metal file. As the angler descends through the different grades the finish improves until the 1 micron that will result in a polished surface.

To file, grain and polish the angles of a single cock shown below plus straight grain its walls requires approximately one hour. In addition is the process of decoration of the flat surface followed by the plating process. After this is complete the jewel is added.

A cock prior to being angled.

After the angles are made and polished.

By way of an example, one angle on the cock below is dressed and polished, conventionally each step would be continued around its periphery.

The first cut made with a file.

The process nearing completion after having used the series of laps.

Polishing the angle with a diamond paste.

Dressing the filed angle with a 30 micron lap.

The surface of the 1 micron paper.

Cleaning off the diamond paste.

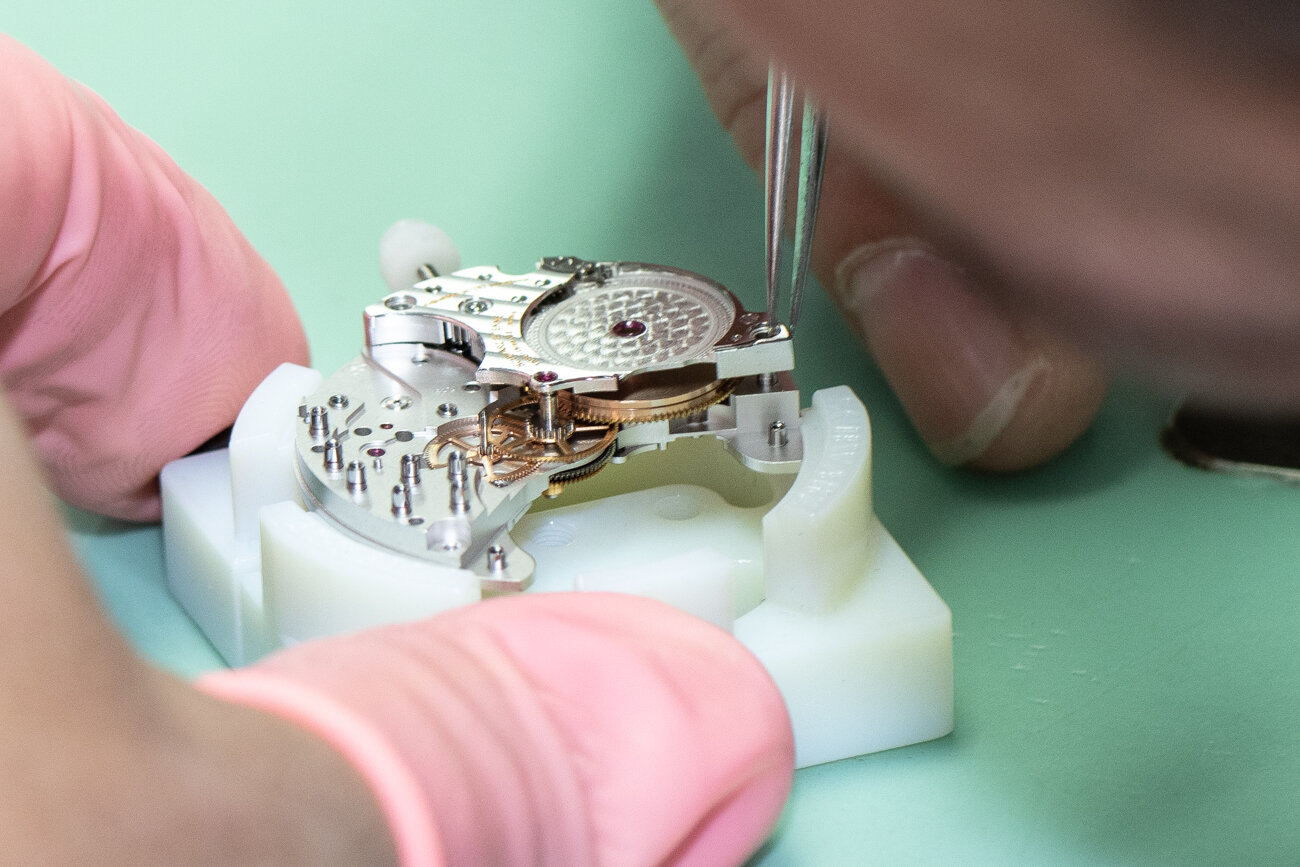

Assembling the movement.

Joaquin assembles the movement.

The movement in its tailor-made holder. The barrel being placed into position.

The 3rd wheel cock being screwed into place.

The ratchet wheel being added and screwed in place.

The barrel bridge being added.

The 4th wheel and cock in place and the escape-wheel cock being screwed down

The Swiss anchor and cock being screwed in place.

The balance cock being placed into position.

The movement assembled except for the automatic module.

The micro-rotor module being positioned.

The finished calibre still in its movement holder.

The assembled movement.

The calibre is unusual in construction allowing for the possibility of two barrels increasing slightly the power reserve but also increasing the torque transmitted through the going train when required to drive modules of high power consumption. Shown here with micro-rotor instead of the second barrel turning the movement into an automatic winding movement.

The final assembly

The movement placed in its movement ring for casing up.

The dial positioned on the movement.

The hands pushed in place.

The movement, dial, hands assembly slid into the case and secured by 2 casing screws and bridals.

The case-back in place.

Summary

Conception, April 2020, design and development completed mid-July, project launched early September, assembly early December, 9 months from beginning till completion.

Processes used during the project; design by hand (Deborah), wire erosion, cnc machining (Damien), hand enamelling (Deborah and Juan), hand engraving (Laura & Christophe), hand miniature acrylic painting (Deborah), lapping of pyrite (exterior supplier), hand angling and straight graining (Sam), printing of text (exterior supplier). All assembly executed by hand, dial (Dorian), Movement (Joaquin), final assembly of the watch (PSM).

This project was made possible by Mauro Egermini and Christophe Blandenier.

Mauro Egermini CEO of Schwarz Etienne, Peter Speake co-founder of The Naked Watchmaker, Christophe Blandenier founder/owner of Les Ateliers Blandenier.

Associated blog post; The End Of The Story

To learn more about Schwarz Etienne and Les Ateliers Blandenier

(For information concerning the price of the Phoenix please contact Schwarz Etienne.)